Service hotline

+86 0755-83044319

release time:2025-04-09Author source:SlkorBrowse:2245

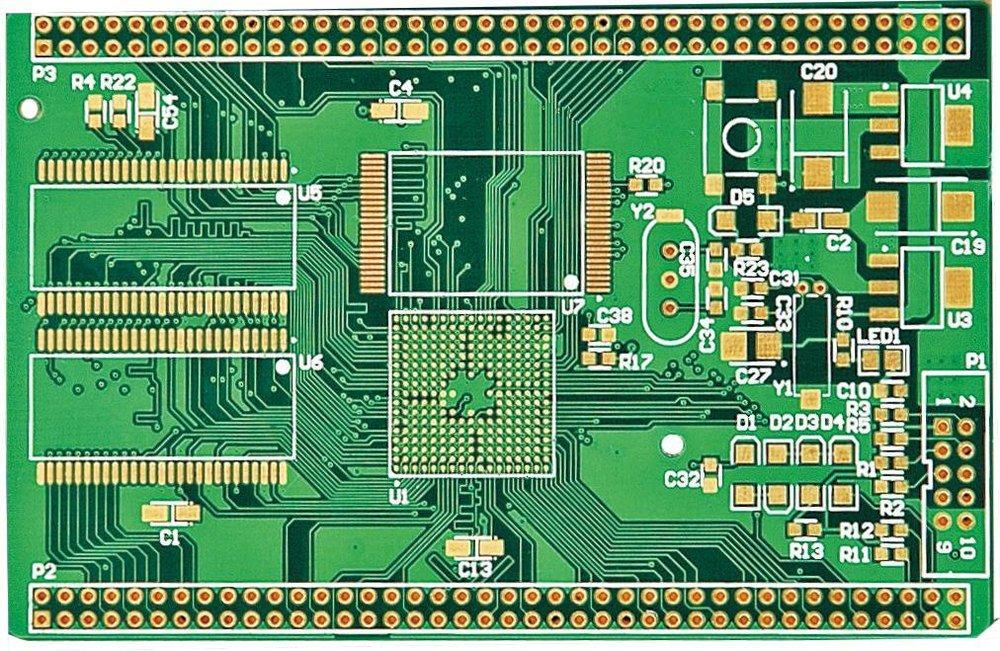

A Printed Circuit Board (PCB) serves as the backbone of modern electronics, enabling seamless connectivity between components. For procurement and engineering teams in consumer electronics, understanding PCB design, manufacturing, and selection is critical. This article delves into the development history of PCB, its core characteristics, key parameters, functional roles, diverse applications, and trusted manufacturers.

The origins of PCB technology trace back to the early 20th century. In 1936, Paul Eisler patented the first functional PCB, revolutionizing electronics assembly. During World War II, mass production techniques emerged, replacing bulky wiring with compact boards. The 1950s introduced double-sided designs, while the 1990s saw multilayer and flexible PCB innovations. Today, advancements like high-density interconnect (HDI) boards dominate industries. This evolution underscores the PCB's pivotal role in miniaturizing devices and enhancing performance.

Modern PCBs exhibit distinct characteristics that define their reliability and efficiency. Below are three critical attributes:

Most PCBs use FR-4, a flame-resistant epoxy laminate. High-frequency applications employ Rogers or Teflon, offering superior signal integrity. Material choice directly impacts thermal stability and durability.

Single-layer boards suit basic circuits, while multilayer designs (up to 50 layers) support complex systems. Layers are interconnected via vias, ensuring precise signal routing.

Advanced PCBs integrate heat sinks and thermal vias to dissipate energy. This prevents overheating in high-power devices like smartphones and servers.

Selecting the right PCB requires evaluating technical parameters. Critical factors include:

Adherence to standards like IPC-6012 ensures quality and consistency across manufacturers.

PCBs perform multifaceted roles in electronic devices. They provide mechanical support, electrical connectivity, and thermal regulation. For instance, in smartphones, PCBs route signals between processors, cameras, and sensors. Their compact design enables sleek, lightweight products without compromising functionality.

The applications of PCB span numerous sectors. Key examples include:

Each application demands tailored PCB configurations, balancing cost and performance.

Partnering with reputable manufacturers ensures quality and compliance. Leading companies like TTM Technologies and Jabil Circuit specialize in high-volume production. Key selection criteria include:

From their historical roots to cutting-edge innovations, PCBs remain indispensable in electronics. By mastering their characteristics, parameters, and applications, procurement and engineering teams can optimize product designs and supply chains. Staying informed about industry trends and trusted manufacturers ensures competitive advantage in a rapidly evolving market.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd