Service hotline

+86 0755-83044319

release time:2025-04-09Author source:SlkorBrowse:2984

On the Cliff Edge of the Semiconductor World

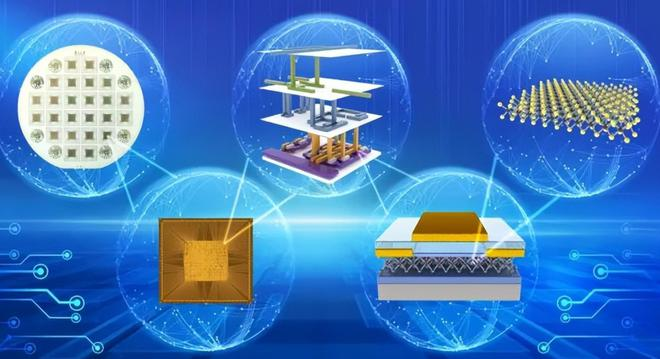

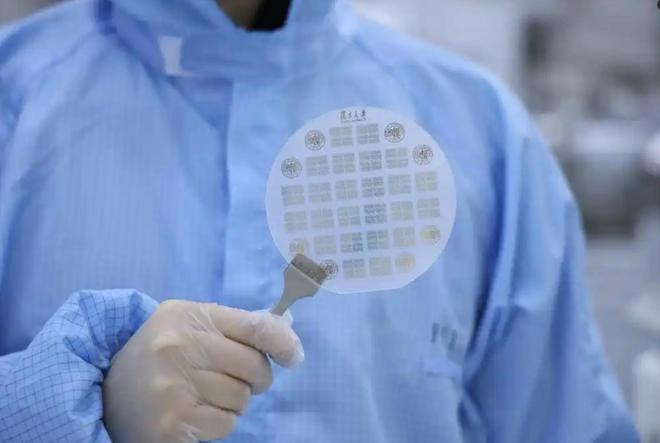

The harsh reality of chip manufacturing is that traditional silicon-based approaches have been locked into the abyss of 5nm and 3nm by EUV lithography machines, with every additional nanometer requiring billions in investment. Yet, the Fudan team chose the path of two-dimensional semiconductors—like carving a new staircase on a sheer cliff. Their molybdenum disulfide material, just three atomic layers thick, enables electron mobility five times faster than silicon, with standby power consumption only 20% of conventional chips. This "painting on rice paper" level of precision even left Science magazine marveling at how it "redefines the boundaries of semiconductor physics."

A Quantum Leap Forged Over a Decade

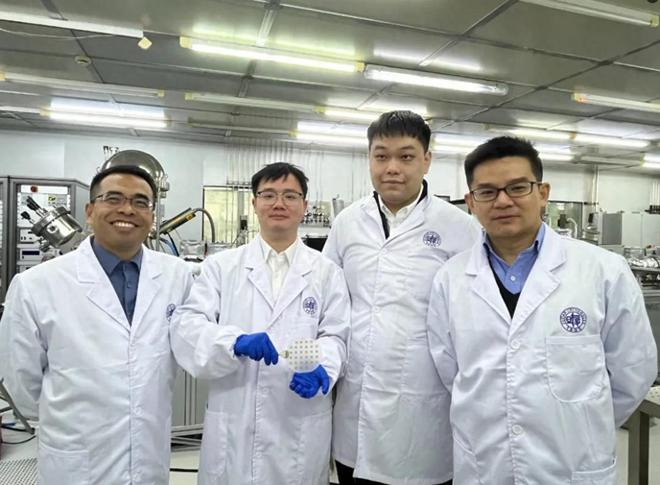

Looking back at the evolution of this technology reads like an epic of Chinese scientific perseverance: In 2015, when the team first grew 2D materials on 12-inch wafers, international peers declared that "mass production would take at least two decades." By 2021, they used AI algorithms to optimize atomic-layer interfaces, boosting device yield from 37% to 89%. And now, the "Wuji" chip has shattered all doubts with its 4.2 billion operations per second. Even more astonishing is that 70% of their process leverages existing silicon production lines, while embedding over 20 proprietary patents at critical stages—this "sailing the seas with borrowed boats" strategy suddenly makes the $120 million EUV lithography machines seem cumbersome and obsolete.

The Quiet Industry Storm Behind the Power Revolution

Beyond the lab data, a silent industrial revolution is brewing. When the power consumption curve of the "Wuji" chip appeared in a strategic meeting at a leading smartphone manufacturer, the IoT device lead’s eyes lit up: "This standby power could triple the battery life of smartwatches!" Automakers, meanwhile, were drawn to its stable performance in extreme temperatures ranging from -40°C to 125°C. The deeper implication lies in the compatibility of 2D semiconductors with existing silicon production lines—meaning China could potentially leapfrog the EUV chasm and use mature 28nm processes to produce ultra-low-power chips rivaling 5nm performance.

The New Dialectics of Tech Competition

Western observers are re-evaluating China’s innovation logic: While ASML pours R&D into 2nm lithography machines, Chinese scientists have proven with 2D materials that "thickness matters more than area." While TSMC carves trillions of transistors into silicon wafers, the Fudan team has built new electronic superhighways between atomic layers. This "you fight your way, I fight mine" strategy is forging a new survival philosophy in the chip industry—after all, in trillion-dollar markets like wearables and edge computing, users couldn’t care less whether a chip is 7nm or 70nm; they only care if the device can last three years without charging.

At this historic juncture that rewrites the rules of the game, perhaps we need to reconsider the true meaning of "overtaking on the curve": Chinese scientists have spent a decade building a "Babel Tower" independent of EUV in the quantum world of two-dimensional materials. When the "Wuji" chip lit its first signal in the lab, it illuminated not just the future of domestic chips, but also another possibility for humanity to push the limits of physics—after all, in the long river of technological evolution, there has never been only one truth, just as the world of chips was never meant to have silicon as the sole answer. Will this quiet revolution ultimately reshape the global semiconductor landscape? Perhaps the answer lies in Professor Zhou Peng's words: "When we stopped obsessing over chasing taillights, we finally saw the stars and the sea."

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd