Service hotline

+86 0755-83044319

release time:2025-03-11Author source:SlkorBrowse:5046

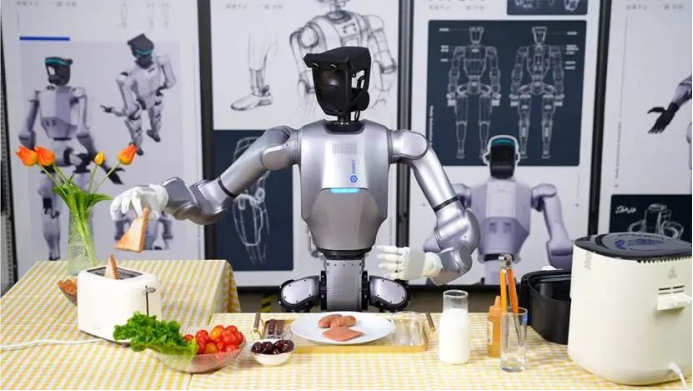

Today, Dobot Technology announced the release of the world's first "dexterous manipulation + straight-knee walking" embodied intelligent humanoid robot, capable of cross-scenario and multi-unit collaboration to handle complex operational tasks.

Equipped with the company's self-developed Neural Drive Dexterity System (NDS) and Anthropomorphic Straight-Knee Walking System (AWS), it leads the deep integration of embodied intelligence technology into industrial, service, and other diverse scenarios.

Straight-knee walking and tool-making are core traits that distinguish humans from primates. According to reports, straight-knee walking (a walking style where the knee joint is fully extended during the gait cycle) is a remarkable feature in human evolution. It consumes only 1/4 of the energy compared to the bent-knee walking of chimpanzees. Through energy efficiency, stability, and functional expansion, it enables clear division of labor between hands and feet—feet support the body while hands perform fine manipulations. This directly facilitated tool use, social collaboration, and brain development.

Based on in-depth reflections on human evolution, Dobot Technology has launched the full-size bionic humanoid robot Dobot Atom, designed for industrial-grade precision operations. Dobot Atom features neural-driven dexterous manipulation and anthropomorphic straight-knee walking. Standing at 1.53 meters tall and weighing 62 kilograms, this industrial-grade humanoid robot is built for "work." It adopts a 1:1 human arm configuration design, with 41 degrees of freedom across its body. It is equipped with a 7-degree-of-freedom industrial-grade bionic collaborative arm with a repeat positioning accuracy of ±0.05mm, suitable for delicate tasks on common 700-1000mm workbenches, and capable of stable navigation in industrial environments.

As one of the few collaborative robot companies globally with full technical chain R&D capabilities, this humanoid robot's core components and software/hardware systems are based on self-developed industrial-grade solutions. It targets scenarios such as material handling in car factories, multi-device beverage preparation in coffee shops, and nighttime medication retrieval in chain pharmacies—environments where equipment positions are not fixed, product specifications vary, and operations are highly similar, requiring short-distance navigation through narrow spaces and flexible turning. Dobot has already initiated collaborations with leading domestic car manufacturers, electronics factories, and coffee/tea shops, with trial production and mass production expected by mid-year.

It is reported that Dobot has a leading advantage in customer and scenario accumulation in the industrial manufacturing sector, where embodied intelligence is being implemented. As the first collaborative robot company to go public in China, Dobot has been successfully applied in factories of numerous global advanced manufacturing enterprises. With a rich portfolio of customer cases and application scenarios, it has deployed over 80,000 units across 15 major industries, including automotive, new energy, 3C electronics, metal processing, and home appliances, spanning more than 80 countries and regions. It has served over 80 Fortune 500 companies, providing critical support for the intelligent upgrade of global industrial manufacturing.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd