Introduction: In the ever-expanding application of timing scenes, electronic systems have put forward higher and more complex technical requirements for timing elements, while the traditional Shi Ying crystal oscillator can't overcome its inherent limitations, such as being afraid of falling and vibration, easy to break, easy to drift in temperature, limited frequency and so on. It can't meet that requirement of all application fields. Compared with Shi Ying crystal oscillator, MEMS silicon crystal oscillator has the advantages of non-oscillation, no deviation, no fear of falling, no temperature drift, small volume and programmability, which will have the opportunity to replace the traditional Shi Ying crystal oscillator and solve the pain points of electronic engineers' design. I love the original MEMS application project of the solution provider, which brings together six advantages of MEMS engineering to help engineers deeply understand MEMS crystal oscillator products, technologies, alternative cases and recommended application fields. This project is supported by the original factory and agents, and we provide free samples for engineers who need to import the project, so that engineers can use them at will.As the advantages of MEMS are gradually understood by engineers and its applications in the fields of automobile, communication, network equipment and industry are rapidly increasing, its cost and programmable usability are constantly improving, and its applications are constantly penetrating into consumer fields such as wearable and smart home. By comparing Shi Ying crystal oscillator with MEMS crystal oscillator, I love the scheme network to help engineers choose the type and improve their ability to introduce new products. In addition to the cost factor, compared with the traditional Shi Ying crystal oscillator, MEMS silicon crystal oscillator is changing the electronic timing market by virtue of its advantages of simplifying the system design, high quality and reliability, low sensitivity to EMI and vibration, less space between boards and stronger impact resistance. We believe that more electronic engineers are introducing MEMS silicon crystal oscillator with greater advantages.

In addition, according to relevant market research institutions, due to 5G, Internet of Things (IoT) and autonomous driving, the MEMS oscillator market will reach 10 billion USD by 2024. SiTime has begun to focus its strategic objectives on expanding the markets of automobiles, Internet of Things and 5G/ communication. Compared with the traditional Shi Ying crystal oscillator, the new MEMS oscillator is entering the major application markets with the following six advantages.

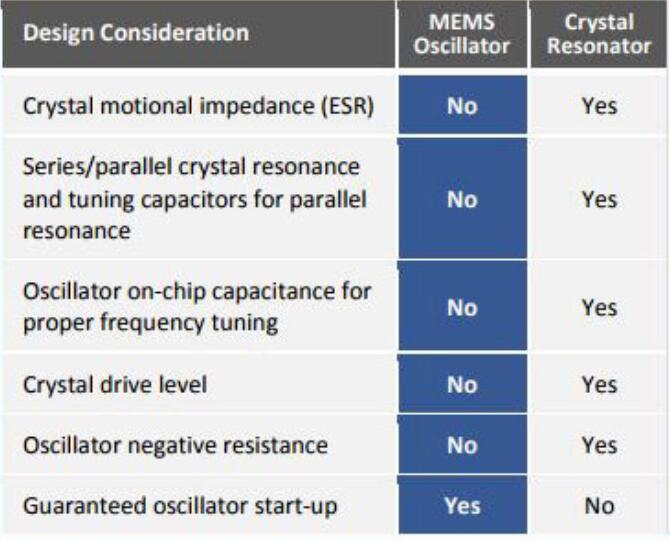

1、MEMS oscillator simplifies the system design.

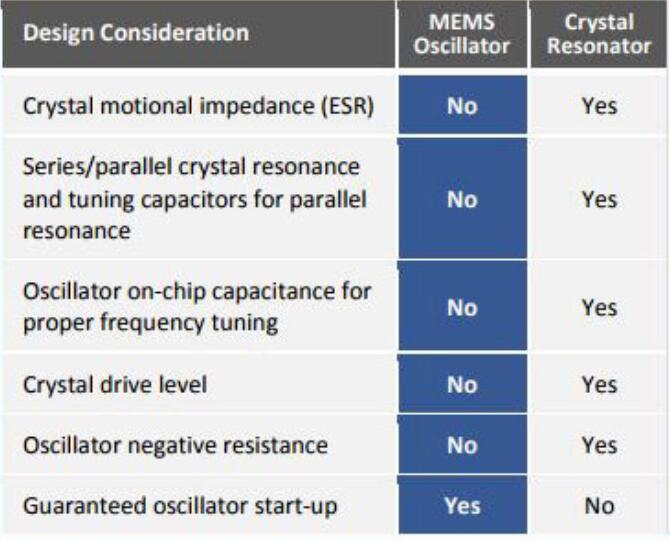

On the surface, the design of oscillator using Shi Ying crystal seems straightforward, especially considering the maturity of this technology. However, countless design parameters need to be considered when matching the crystal with the oscillator circuit. These parameters include crystal motion impedance, resonant mode, driving level and negative resistance of the oscillator, which are indicators to measure the gain of the oscillator.In addition, the parallel resonant mode crystal must consider the load capacitance, which should consider the parasitic capacitance of PCB and the on-chip integrated capacitance that may be included in the oscillator circuit. All these parameters must be carefully considered to ensure the reliable start-up and operation of the circuit. Because the oscillator circuit requires the close matching between the resonator and the oscillator circuit, the crystal supplier cannot guarantee the start-up of the crystal.  On the contrary, MEMS oscillator is a complete solution. The oscillator manufacturer matches the quartz resonator with the oscillator circuit, thus reducing the burden of circuit board designers. As the matching error is eliminated, SiTime guarantees the start-up of the oscillator. In short, MEMS oscillator is a plug-and-play solution, which greatly simplifies system design.

On the contrary, MEMS oscillator is a complete solution. The oscillator manufacturer matches the quartz resonator with the oscillator circuit, thus reducing the burden of circuit board designers. As the matching error is eliminated, SiTime guarantees the start-up of the oscillator. In short, MEMS oscillator is a plug-and-play solution, which greatly simplifies system design.

2、And provide high quality and high reliability.

Compared with the special manufacturing process of Shi Ying crystal, MEMS oscillator manufacturers adopt the standard semiconductor packaging process, which includes the production of silicon wafer-level resonator and oscillator integrated circuits, and the mold combination with the plastic packaging of standard lead frames.SiTime's MEMS First process uses standard silicon manufacturing technology to seal MEMS in a very high temperature, clean and vacuum environment. This creates a very clean and moisture-free environment for MEMS, and eliminates the possibility of Activity Dip caused by pollution or moisture.All SiTime products are designed and put into production by powerful 6-Sigma process. Products shall be fully characterized and identified according to appropriate JEDEC and AEC standards. In order to ensure the highest quality, SiTime performs batch acceptance test (LAT) on the temperature range on the samples of each production batch. The ultra-high quality of SiTime has been verified in thousands of devices. Its actual field scrap rate is lower than 2 DPPM, ranking first in the semiconductor industry. After more than six years of shipment, SiTime has no faults in MEMS field.

3、MESM oscillator has low EMI sensitivity.

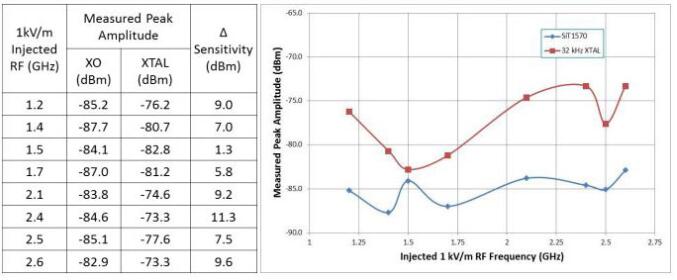

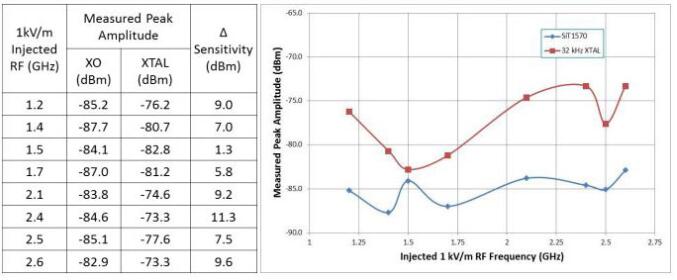

Electromagnetic energy, which is common in most systems, can connect the crystal resonator and the integrated circuit containing the oscillator circuit through the exposed PCB traces. This noise can be coupled into the oscillator circuit and transmitted to the output terminal, thus increasing the jitter and noise of the system. However, the integrated oscillator has no exposed PCB connection between the resonator and the oscillator IC, and the bonding wire or ball connecting the MEMS resonator and the IC is very short. This makes MEMS oscillator less sensitive to electromagnetic interference. As shown in the following table and figure, SiTime silicon crystal oscillator is 11.3dBm lower than crystal resonator (134 times in linear scale).

4、MEMS oscillator occupies less board space.

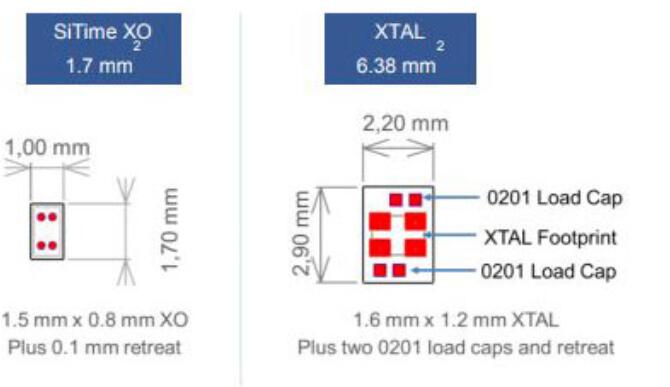

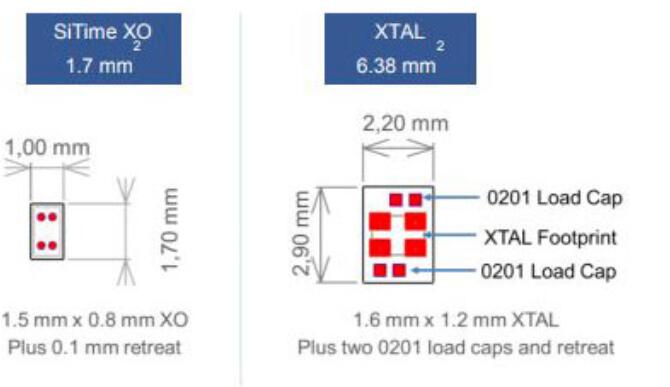

MEMS oscillator is a fully integrated solution, which does not require external components, such as power decoupling cover. SiTime's 1.5mm x 0.8mm (1508) footprint is smaller than the smallest Shi Ying crystal footprint of 1.6mm x 1.2mm. When the load capacitance required by 32kHz Shi Ying crystal is taken into account, the total plate area or the volume of Xtal solution is more than three times that of the original.

5、Lower vibration sensitivity and stronger impact resistance.

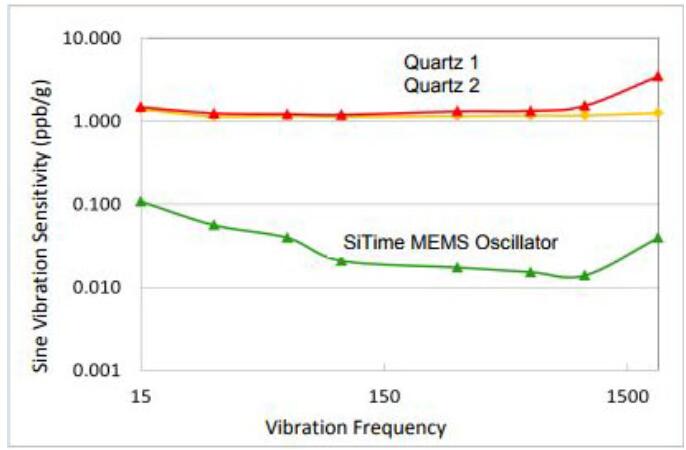

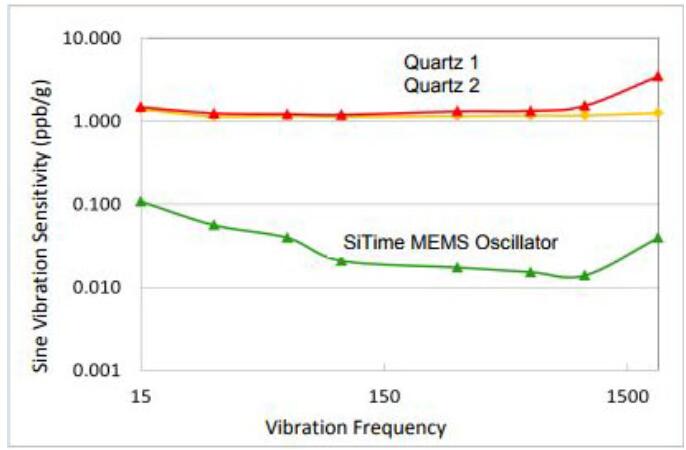

Compared with the similar Shi Ying crystal oscillator, time MEMS oscillator has lower vibration sensitivity and stronger impact resistance. Some systems that need very stable frequencies, such as wireless base stations and small cells, may have system failures and service interruptions due to vibration. SiTime MEMS oscillator has anti-vibration ability, because the mass of MEMS resonator is about 1,000 to 3,000 times lower than that of quartz resonator. This means that applying a certain acceleration, such as shock or vibration, to MEMS structure will result in a force much lower than its Shi Ying, and thus a lower frequency shift.  Fig. 5 shows that the vibration sensitivity of SiTime MEMS oscillator is 10 times lower than that of Shi Ying oscillator. Please note that this figure is based on the measured Shi Ying oscillator, not the passive crystal resonator, but the similar result is the expected quartz crystal resonator.

Fig. 5 shows that the vibration sensitivity of SiTime MEMS oscillator is 10 times lower than that of Shi Ying oscillator. Please note that this figure is based on the measured Shi Ying oscillator, not the passive crystal resonator, but the similar result is the expected quartz crystal resonator.

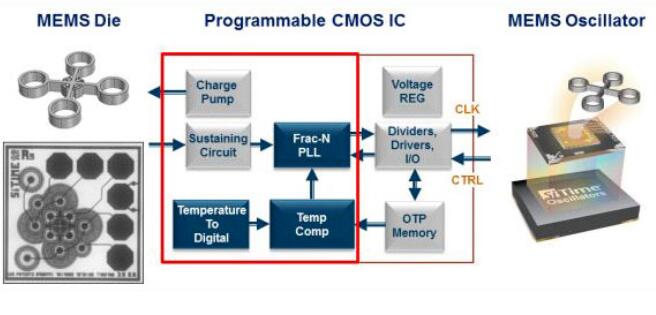

6、Any frequency of MEMS oscillator is easily available.

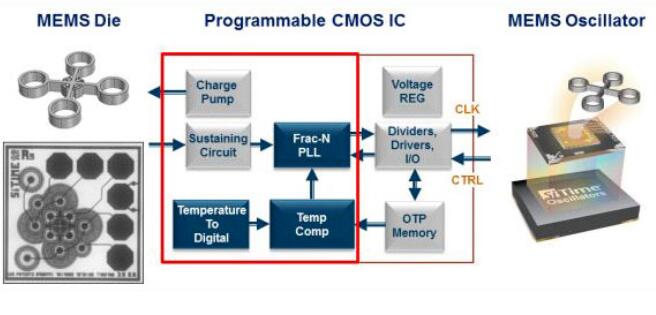

Compared with crystal resonator, MEMS resonator is based on standard resonator structure. The output frequency of MEMS oscillator is generated by programming PLL with different multiplication values. This makes the frequency range very wide and the accuracy reaches six digits. In addition, MEMS silicon oscillator is made of standard semiconductor technology and package. Because MEMS oscillator manufacturers use very large semiconductor industry infrastructure, the capacity is virtually unlimited.MEMS oscillator samples can be programmed and obtained in one day, even for non-standard frequencies. By using SiTime's low-cost time machine II programmers and field programmable oscillators, designers can immediately program oscillators in their laboratories to create any frequency of a device, any power supply voltage and any stable device within the operating range of the device.

二、Scene application of MEMS crystal oscillator

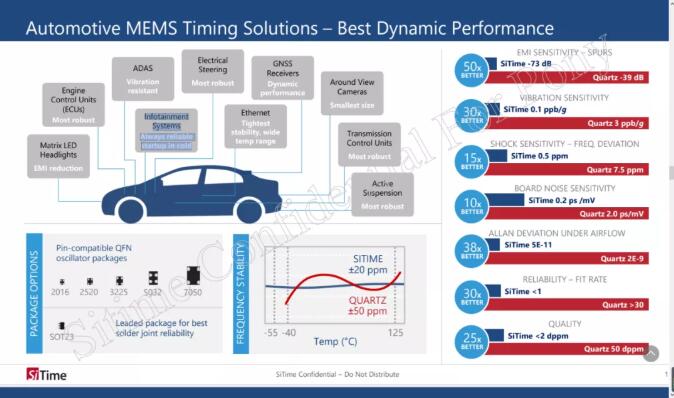

2.1, automotive MEMS timing solution

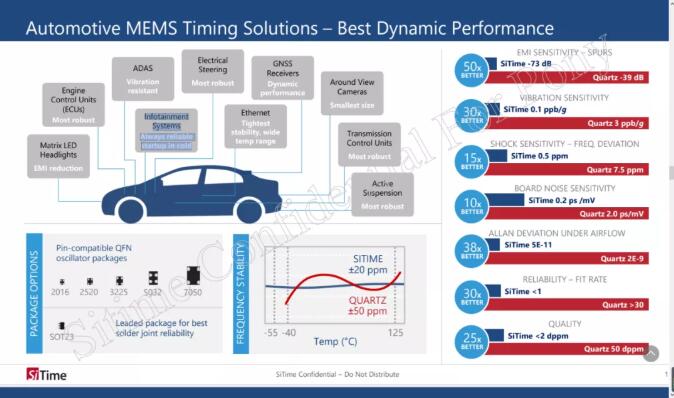

Aiming at the application of automobile timing system, SiTime Company, by virtue of breakthrough technology and rapid innovation, has covered automobile camera, ADAS computer, Ethernet, radar and laser radar, high-precision global navigation satellite system, infotainment system, engine and power system, wireless charger, etc. Its automotive MEMS oscillator products are 30 times more robust and AEC-Q100 compatible. It is designed for automotive applications that conform to ASIL (Automotive Safety Integrity Level), such as advanced drive assist system (ADAS), vehicle Ethernet, powertrain and electronic control unit (ECU).Secondly, according to the data of SiTime, each car has 20-70 oscillator opportunities, and the cost of each MEMS car is 3-10 USD. The advantages of MEMS oscillators in these extreme temperature and severe vibration environments are as follows: 1. The best stability ± 20ppm, extended temperature from -55oC to 125o, shock resistance, vibration and noise 50 times better than Shi Ying oscillator; 2. Best manufacturability. SOT23 has the best solder joint reliability and easy visual inspection; EMI control, no PCB change, configurable rise/fall time control.

In short, SiTime has powerful oscillators such as SiT2024, SIT8925, SiT8924, SIT8925, etc. They are the best solutions for automotive applications, because they conform to ASIL (Automotive Safety Integrity) vehicle Ethernet, powertrain and electronic control unit (ECU) of ADAS.

2.2. Application of MEMS silicon crystal oscillator 5G

In the field of 5G/ communication, SiTime cooperates with industry leaders such as Intel to promote the timing innovation of 5G.

According to Rajesh Vashist, CEO of SiTime, "For a variety of reasons, 5G technology will bring far more pressure to timing solutions than in the past. The 5G radio uses millimeter wave technology, covering a few hundred meters, instead of the kilometer distance of 4G. Therefore, the 5G network will be more dense. A denser network makes the equipment closer to customers, and enters a more rigorous and less controlled environment, such as deployment in traffic lights, street lamps, buildings, roofs and parking lots.These locations have many environmental pressure factors, such as vibration, shock, high temperature and rapid temperature change. These pressure factors lead to the failure of Shi Ying devices, which we think may be the single biggest failure point in 5G. Emerald products are 20 times more immune to these environmental stress factors, and ensure that the network and mission-critical services running on the network run well.Considering the denser deployment configuration of 5G, higher bandwidth and deployment of mission-critical services, the standard organization is making the radio-to-radio time accuracy specification 10 times stricter. In 4G, it is 1.5 microseconds. In 5G, it is 130 nanoseconds (ns). In order to meet this strict specification, SiTime introduced Emerald products.This is the first MEMS-based thermostatic crystal oscillator (OCXO). They are designed to solve problems related to quart OCXO, which are very sensitive to high temperature, hot slope and vibration. Designers usually need to make 3 to 5 circuit board iterations to properly place Shi Ying OCXO. If the design still shows sensitivity, they must use plastic or metal covers to install Shi Ying OCXO to isolate it from the surrounding environment. RajeshVashist said that Emerald Platform eliminated this problem. Its powerful OCXO can be placed anywhere on the circuit board. When customers get the right position for the first time, they can launch products more quickly and speed up their revenue time.Besides solving circuit board design problems, Emerald Platform also sets a new performance benchmark in terms of dynamic stability (in the system, there are vibrations, shocks and temperature slopes), which is 20 times higher than that of Shi Ying-the new 5G essential infrastructure deployment Emerald products are programmable and can always provide any frequency from 1 to 220MHz, as well as a series of frequency stability, operating temperature, output types and packages, including a 75% smaller solution than similar OCXO in Shi Ying.For customers, SiTime has eliminated a long list of headaches for customers, and local agents in China provide programming services to solve the problem of timely delivery of engineering samples and bulk orders. For SiTime, Emerald Platform enables it to expand to the higher end of the telecommunications and network timing market worth $1.5 billion.

三、Replacement case of MEMS crystal oscillator

The scene of silicon crystal oscillator replacing Shi Ying crystal oscillator is rapidly improving, especially in the tide of shortage, and the replacement will be more urgent. I love the application cases of communication equipment, industrial control, power supply and FPGA supporting clocks recommended by our solution network in conjunction with Sitime, the original silicon crystal oscillator factory, to help solution providers and terminal equipment manufacturers make selection and substitution, and provide free research and development samples. The frequency point of silicon crystal oscillator has four advantages: no vibration, no deviation, no temperature drift and no fear of falling, which can effectively improve the stability and reliability of products, and is especially suitable for development projects with large temperature difference, large vibration and many frequency points.

Case 1: SIT8008 Low Power Programmable Oscillator

Compatibility: without PCB modification, it can directly replace Shi Ying crystal oscillator;

Frequency accuracy: any frequency point from 1 MHz to 1-110MHZ, with 6 decimal places;Voltage range: 1.8V--3.3V full voltage range;

Package specifications: 7050, 5032, 3225, 2520, 2016 full package range support;

Sample delivery: 24-hour sample supply at any frequency point.

Application scenarios: Ethernet devices, servers, SSD, optical communication, audio and video, industrial control, power supply and other industrial applications.Commitment: immediate delivery, environmental protection, and quality assurance throughout the process.

Case 2: SIT9121 High Performance Differential Crystal Oscillator

Frequency accuracy: any frequency point of 1-220MHZ, with 6 decimal places;Voltage range: 2.5V-3.3V voltage range;Specifications: 7050, 5032, 3225 packages;Output signal: LVDS\LVPECL signal mode;Application scenario: PCI-E clock, SONET device, FPGA clock and system clock, storage device, data center device.

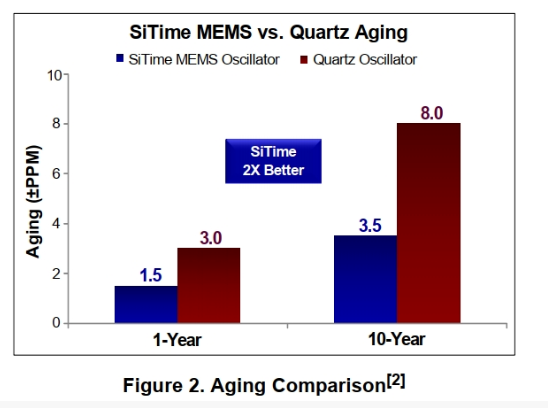

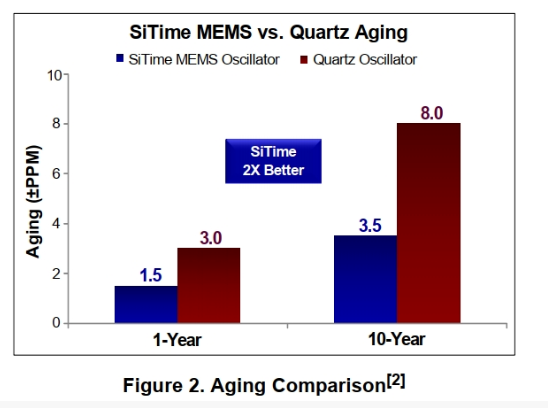

Comparison of aging parameters between silicon crystal oscillator and Shi Ying crystal oscillator

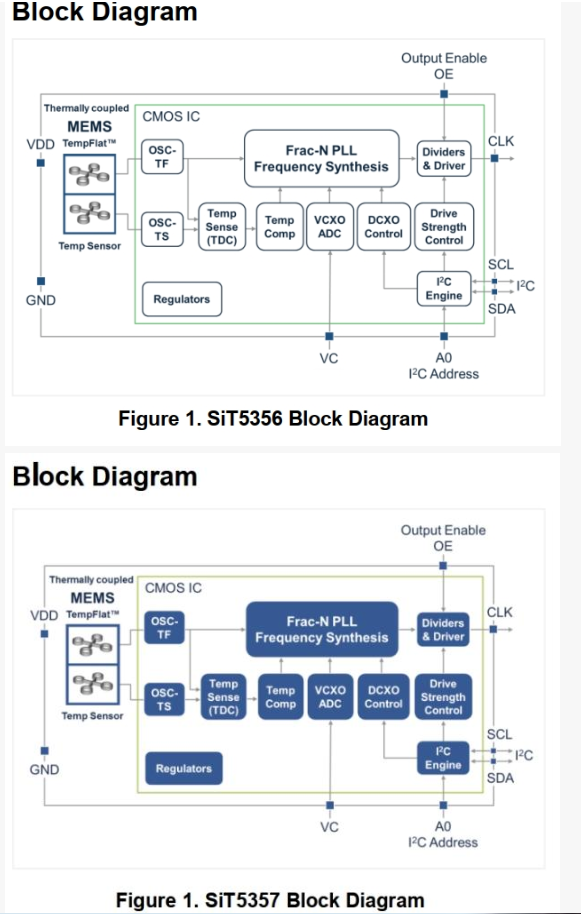

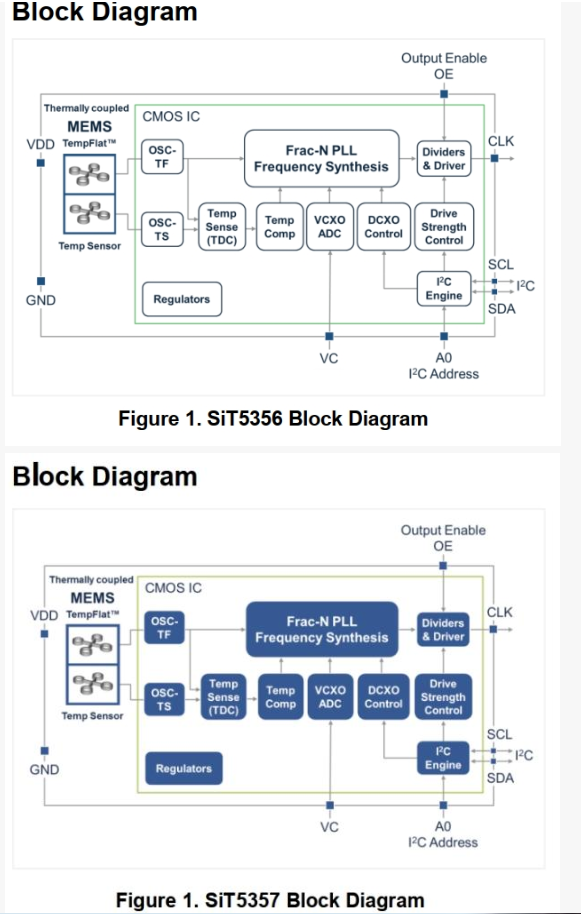

Case 3: SIT535X Temperature Compensated Crystal Oscillator (TCXO)

Temperature compensation range: ± 100ppbupto±

High precision and stability (no temperature drift) in the full temperature range of 220ppb;

Frequency accuracy: any frequency point of 1-220MHZ, with 6 decimal places;

Voltage range: 2.5V2.8V3.3V;

Package specification: 503210-Pin package;

Output: LVCMOS& sine wave output;

Application scenarios: small base station, IEEE1588, GPS/GNSS, synchronous Ethernet equipment, test instruments, radar and other products.

Generally speaking, with the expansion of MEMS silicon crystal oscillator technology, the traditional Shi Ying crystal oscillator will be replaced. Compared with Shi Ying crystal oscillator, MEMS silicon crystal oscillator breaks through multiple technical limitations and solves the difficulties and pain points of clock circuit scheme for electronic design engineers.

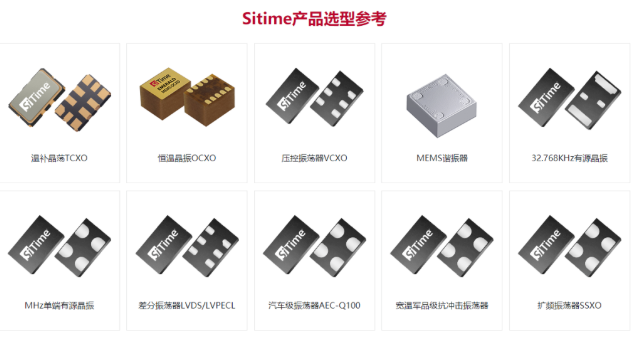

四、Selection of MEMS crystal oscillator products

Si company is the leader of silicon MEMS clock market. SiTime's programmable solutions provide rich features, which can help customers improve their product performance, reduce size, reduce power consumption and improve reliability, so as to improve their market competitiveness. With 80% market share and more than 2 billion MEMS clock devices shipped, SiTime is transforming the clock industry. Time products adopt the production process of standard semiconductor manufacturing process and high-volume plastic packaging technology, providing the strongest supply capacity and the shortest delivery time in the industry.In order to speed up the application and popularization of MEMS silicon crystal oscillator products, to recognize electronic engineers and to select and replace products, domestic electronic solution providers and design engineers can quickly experience the product experience upgrade brought by MEMS silicon crystal oscillator products with high stability, ultra-small package, ultra-low power consumption and ultra-low jitter. SiTime, the leader of MEMS crystal oscillator timing market, has launched a free sample delivery activity in conjunction with My Love Project Network (please click https://activity.52solution.com/sitime/ or click "Read the original" to enter the special page for application for details), and can order products in bulk through cash coupons.

Disclaimer: This article is reproduced from "I Love Scheme Network". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing, and supports the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen