Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:12167

After entering the 21st century, electronic information technology has become the most important technology, and electronic components are the premise of the development of electronic information technology. In order to promote the further development of electronic information technology, it is necessary to improve the reliability of electronic components, so it is necessary to understand the failure mechanism, mode and analysis technology of electronic components.

1.The meaning of invalidation

Failure refers to the failure of electronic components. The important components of various electronic systems or electronic circuits are generally different types of components. When it needs more components, it indicates that the complexity of its equipment is higher; Otherwise, it is low. Generally, the circuit failure is defined as the loss of the specified function of the circuit system.

2.Classification of failure

According to different standards, the classification of failures generally includes the following classification methods.Based on the cause of failure: it is mainly divided into essential failure, misuse failure, accidental failure, natural failure and so on.Take the degree of failure as the standard: it is mainly divided into partial failure and complete failure.Take failure mode as the standard: mainly divided into non-function, short circuit, open circuit, etc.Based on the severity of failure consequences, it can be divided into mild failure, severe failure and fatal failure.In addition to the above, there are many kinds of classification standards, such as failure occasions, failure external manifestations, etc., which will not be described here.

3.Failure mechanism of

The failure mechanisms of electronic components are also classified in different ways, usually based on their causes, which can be divided into the following failure mechanisms.

① Surface deterioration: the sodium ions of components are polluted, which leads to leakage of channel, damage of γ radiation, surface creep or breakdown, etc.

② Deterioration caused by design problems: refers to the design problems in circuit, layout and structure of single component;

③ Internal degradation: refers to the instantaneous power overload and structural performance degradation caused by CMOS blocking effect, secondary breakdown, heavy metal contamination, neutron radiation damage and material problems;

④ Damage caused by improper use: refers to electrical surge damage, electrostatic damage, damage caused by excessive temperature, malfunction caused by interference signals, etc.

⑤ Metallization system deterioration: refers to aluminum electromigration, aluminum corrosion, aluminum gap, etc. in electronic components;

⑥ Package deterioration: it refers to the corrosion and air leakage of pipe legs or short circuit or electric leakage caused by foreign objects in the shell.

4.Common methods of failure analysis

There are many techniques for failure analysis of electronic components, but the commonly used ones are as follows, which are specifically introduced as follows.

4.1 Pull out and insert method. The plug-in method refers to monitoring the process of plug-in and plug-in of component boards or plug-in boards, and judging whether the plug-in connection interface is the place where the fault occurs. It is worth noting that, when failure analysis is carried out by using the pull-out and insert method, there will be special situations in the process of pulling out and inserting the component board or plug-in board, that is, sometimes the place where the state changes is not only the connection interface, but also other parts. Therefore, when applying the pull-out and insertion method, we should pay attention to every part and subtle changes in order to make a correct judgment.

4.2 Sensory discrimination. Sensory discrimination is the way to know the temperature and hardness of components, the smell of nose, and the sound of ears by observing the shape of components and the touch of hands. Sensory discrimination is easy to operate and saves money, but what can be discriminated will be restricted by sensory ability.

4.3 Power supply bias method. Power supply bias method refers to biasing the normal power supply and voltage, making them in abnormal state, and then exposing weak links or faults, which can then reflect the parts of components and components that are or are on the verge of failure. This method is generally used in the case of failure caused by long working hours or preliminary judgment that the power grid fluctuation causes the failure. It is worth reminding that the power supply bias method is destructive to some extent. Before using this method, you must check the insurance coefficient or other factors, and remember not to use it casually.

4.4 Replacement of spare parts. By monitoring the components or parts that are suspected to be taken down, and then replacing them with qualified spare parts, then making a comparative analysis of the fault phenomena, such as whether the fault phenomena disappear or not, and finally determining whether the fault source is in the taken down parts, this method is the replacement of spare parts method.

The above-mentioned methods are frequently used for failure analysis of electronic components. Besides, there are static and dynamic measurement methods. Method of raising and lowering temperature; Pinch positioning method, etc.

5.Thoughts on Failure Analysis

In order to effectively analyze the failure of electronic components, a clear idea must be formed. Failure analysis of general electronic components is mainly carried out step by step according to this idea:

① Determine whether it is invalid;

② Defining the ultimate goal of failure analysis;

③ Starting with the failure phenomenon, list all the doubtful points of the failure position;

(4) Draw up a plan to remove doubts; Analyze the failure position step by step;

⑤ Imagine and enumerate all the possible causes of failure parts;

⑥ Test the assumption by experiment;

⑦ Propose and review the failure prevention scheme;

⑧ Use facts to test whether the failure prevention scheme is effective;Pet-name ruby really implement failure prevention scheme [4].

6.Principle of failure analysis

The failure analysis of electronic components should follow relevant principles, and some commonly used principles are as follows.

6.1 The principle of primary before secondary. Generally, the primary and secondary functions are judged by the degree of failure affecting functions. After defining the major and minor problems, solve the major problems first and then the minor problems.

6.2 Principle of scheme before operation. During the failure analysis, the analyst must be calm first, think of a solution in his mind before operating, and do not blindly operate, which will cause other larger components to fail.

6.3 The principle of general before special. Check the positions with frequent failures first, and then check the positions with less failures.6.4 The principle of weak current before strong current. Generally, in the face of the whole machine with failure or the sample with failure, the input signal, power supply, etc. should be from weak to strong depending on the specific situation when testing its performance or judging the fault position. It is worth reminding that in the whole change from weak to strong, we must closely observe and record the abnormal phenomena. In addition, it is necessary to prevent sudden startup and shutdown caused by excessive power, resulting in power shock, which will eventually disturb the failure state and increase the difficulty of failure analysis [5].In addition, there are the principles of simplicity before complexity, security before power on, macro before micro, peripheral before host, static before dynamic, power off before replacement, public before private, etc.

7.summarize

Through the research on the failure analysis technology of electronic components, we can know the reasons, failure modes, failure mechanisms and some commonly used analysis methods of electronic components. Electronic components are the source of electronic products. In order to ensure the normal and reliable operation of electronic equipment or electronic system, the reliability of electronic components must be ensured. Therefore, it is necessary to master the technology of failure analysis of electronic components.

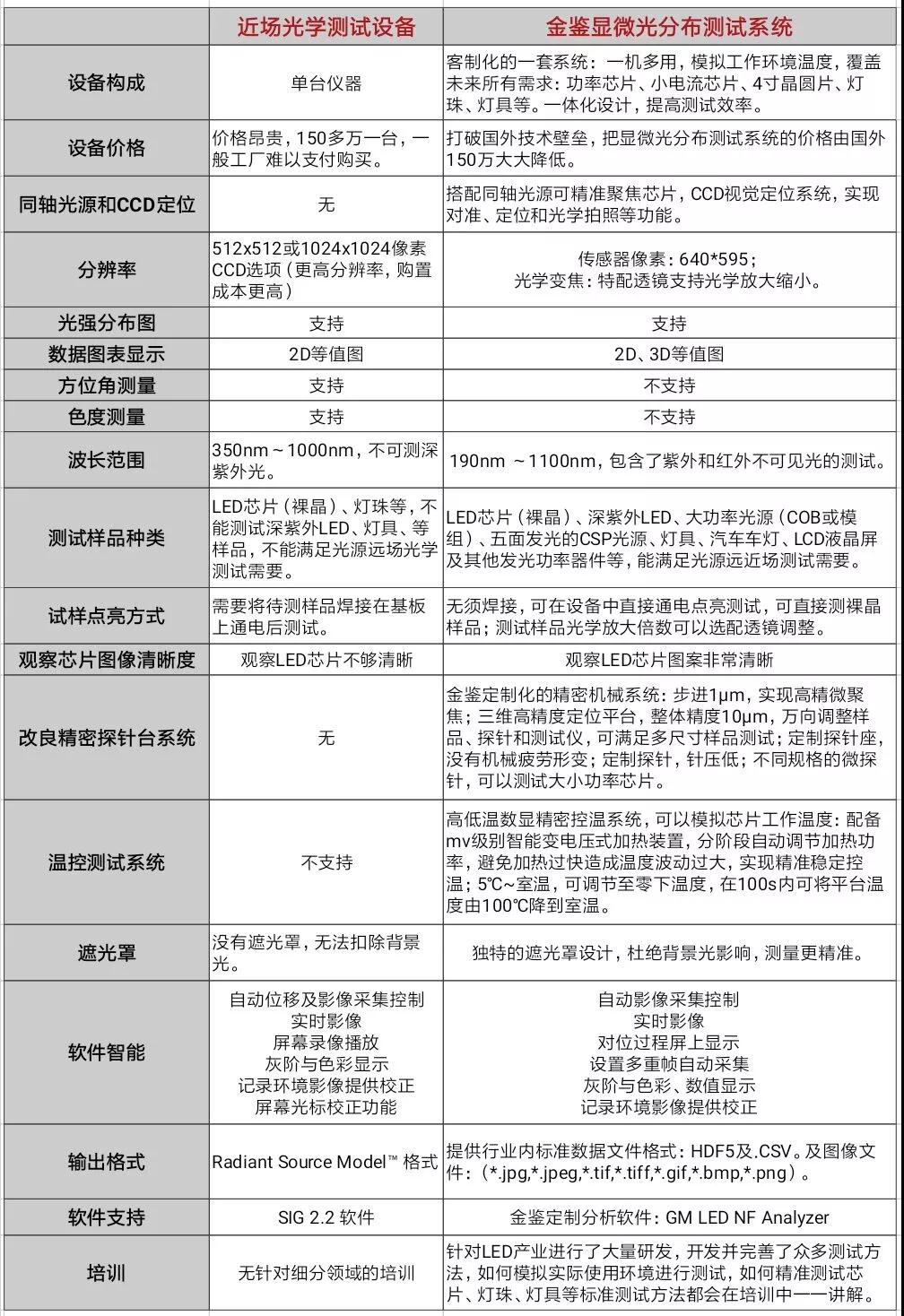

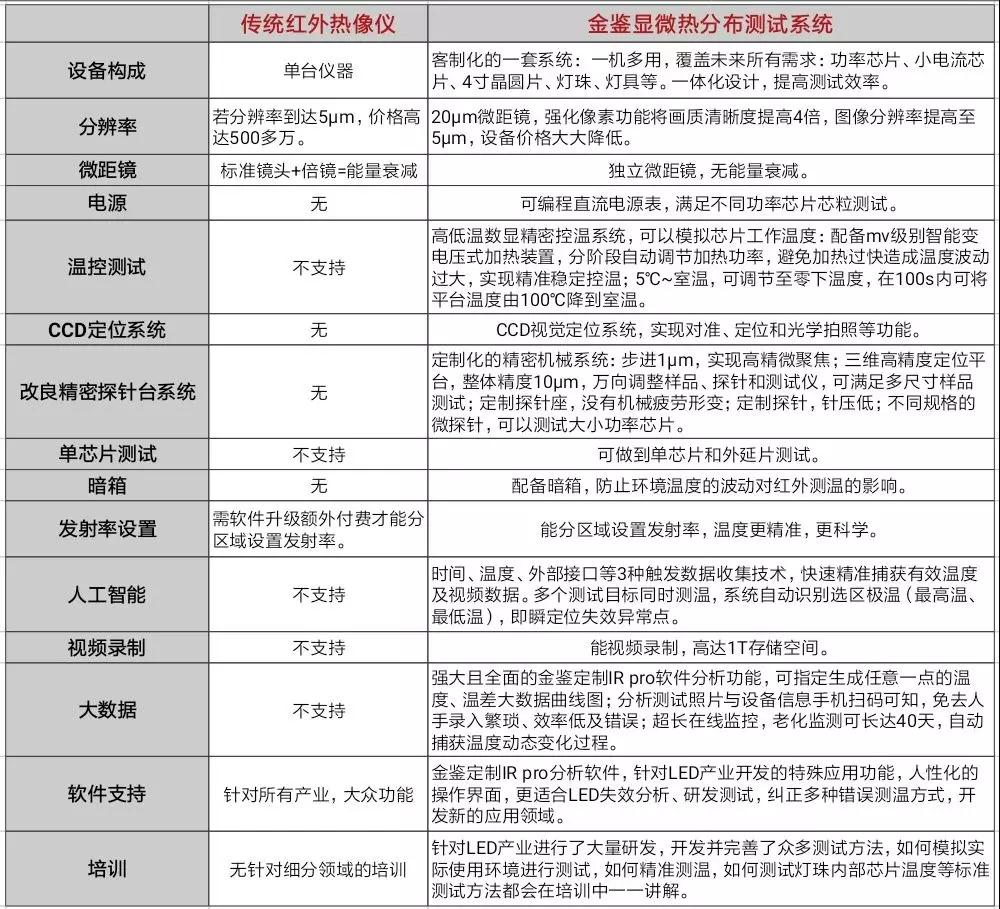

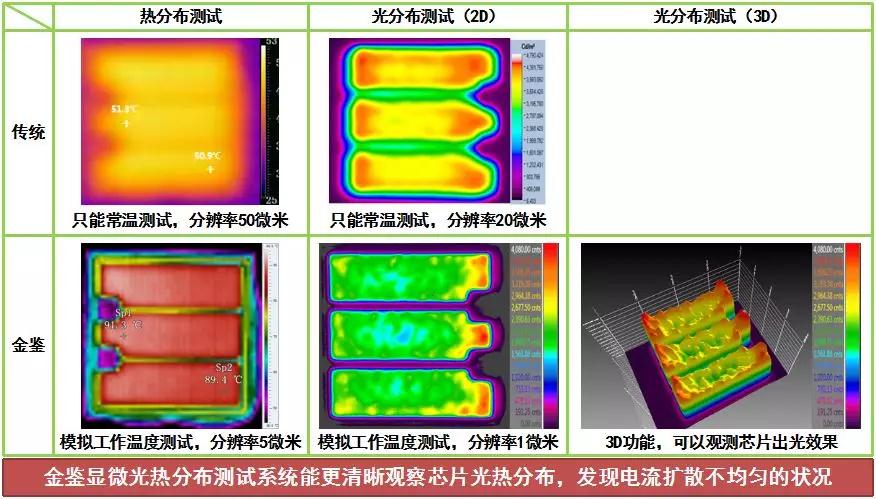

Microscopic light distribution testing system for metallographic examination

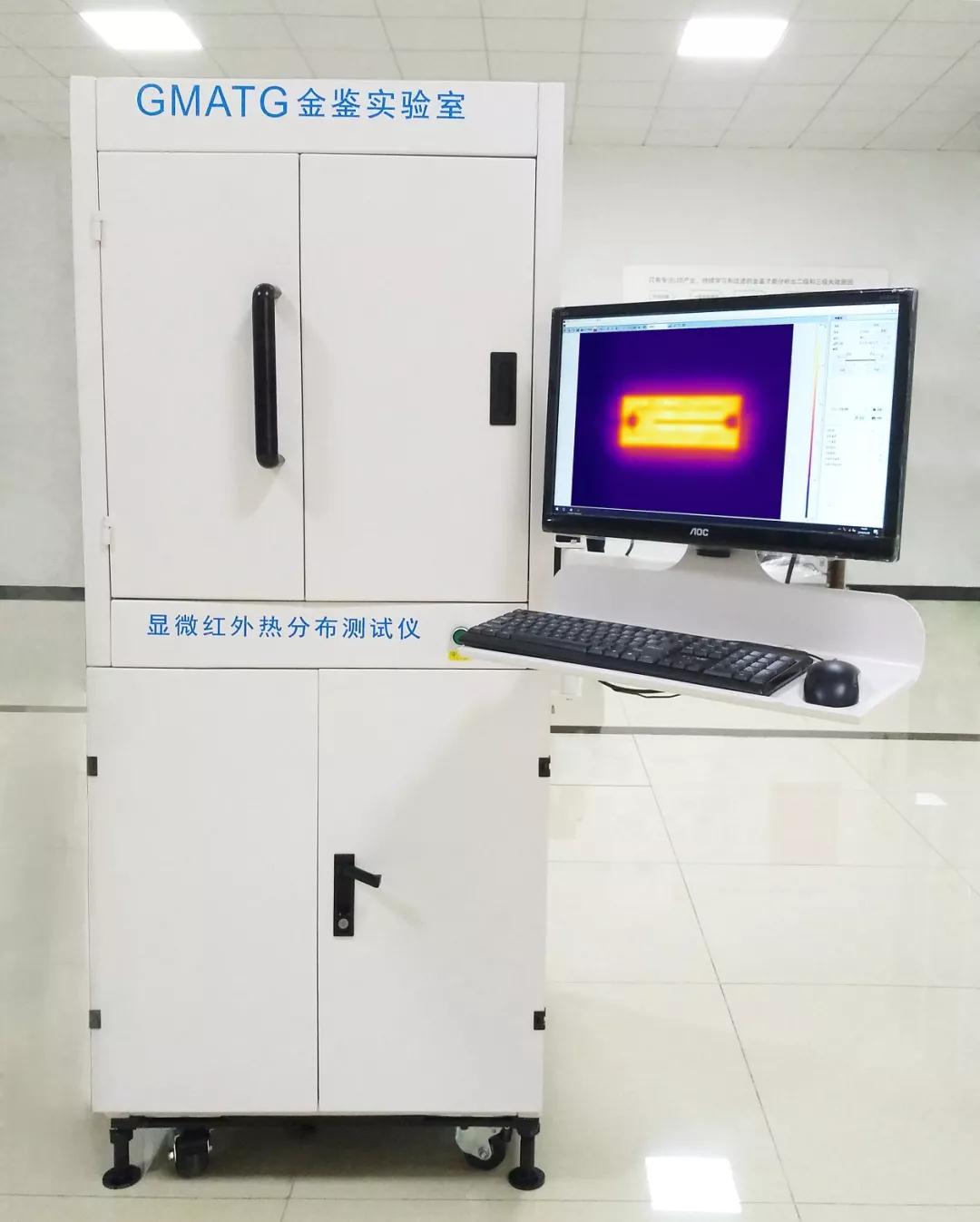

Microscopic thermal distribution testing system for metallographic examination

Note: This article is reproduced from the Internet to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.。

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd