Service hotline

+86 0755-83044319

release time:2024-11-09Author source:SlkorBrowse:12314

In electronic circuits, the Zener diode plays a critical role as a key voltage protection component. The MM1W18, a high-performance Zener diode, has become a top choice for many electronics engineers due to its excellent voltage regulation, high power handling capability, and extremely low reverse current. This article provides a comprehensive overview of the MM1W18, including its product description, performance features, application areas, market prospects, and fault prevention measures, offering readers a thorough understanding and reference.

The MM1W18 is a Zener diode designed specifically for electronic circuits, featuring a nominal voltage regulation of 18V with a voltage regulation range between 16.8V and 19.2V. With a rated power of up to 1000mW, it can withstand significant power dissipation while maintaining stable voltage output. The reverse current (Ir) is only 5µA, ensuring high efficiency in low-power applications.

● High Precision Voltage Regulation: The MM1W18 offers precise voltage regulation, providing stable voltage output in circuits and effectively preventing voltage fluctuations from affecting circuit performance.

Slkor Voltage Regulator Diode MMBZ5243B product photo

● High Power Handling Capacity: With a rated power of 1000mW, the MM1W18 can handle higher power dissipation, making it suitable for high power density applications.

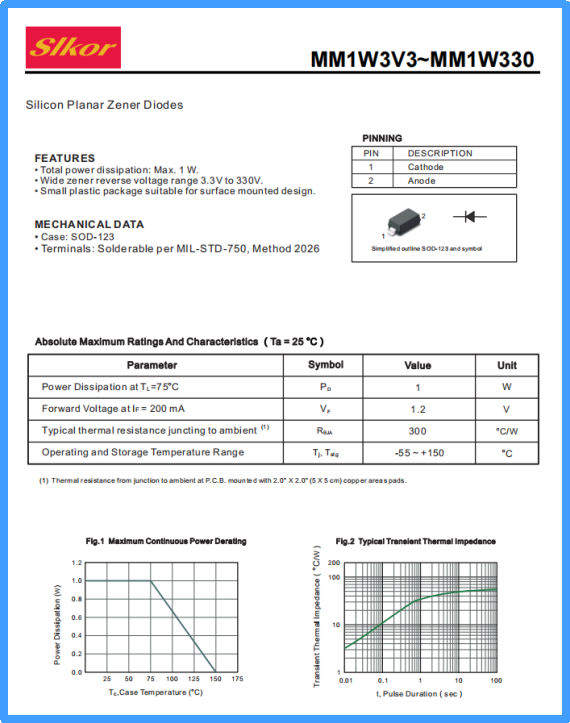

Slkor Voltage Regulator Diode MMBZ5243B specification

● Low Reverse Current: The reverse current of 5µA reduces standby power consumption, extending battery life, especially in low-power electronic devices.

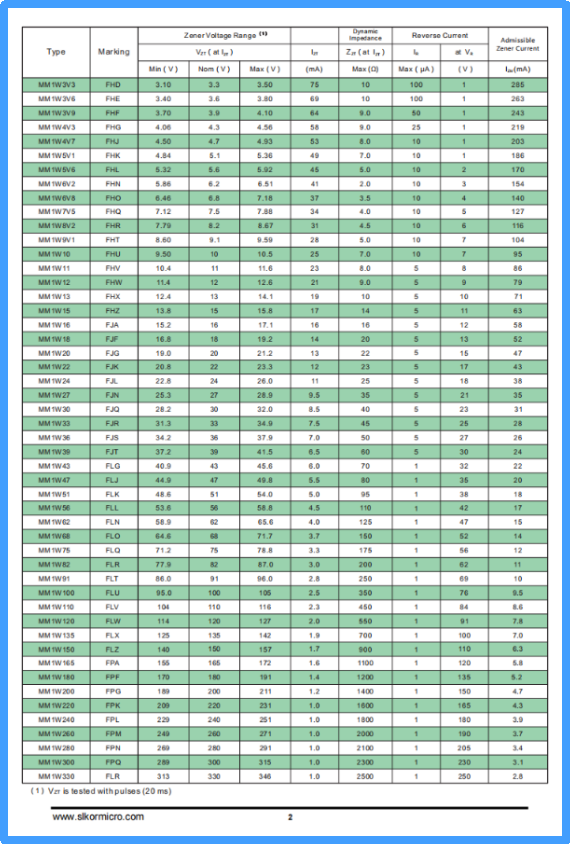

Parameters of Slkor Voltage Regulator Diode MMBZ5243B

● Good Temperature Stability: The MM1W18 maintains stable performance even in high-temperature environments, improving the reliability and stability of circuits.

Choose the Appropriate Package:

● Consider Environmental Adaptability: Choose a package with appropriate environmental compatibility (e.g., temperature, humidity, vibration) based on the application environment. For example, in high-temperature environments, select packages with higher thermal resistance.

● Consider Heat Dissipation Performance: The type of package significantly affects heat dissipation. For high-power applications, opt for packages with better heat dissipation capabilities, such as those with heatsinks.

Limit Power Dissipation:

● Accurately Calculate Power Dissipation: When using the MM1W18, carefully calculate its power dissipation in the circuit to ensure it does not exceed its rated power (1000mW). This can be done using circuit simulation software or by measuring in actual use.

● Use Current Limiting Measures: Add current-limiting components (e.g., resistors, fuses) in the circuit to prevent excessive current that could lead to power dissipation exceeding the rated value.

Enhance Heat Dissipation:

● Use Heatsinks: In high-power density applications, install heatsinks on the MM1W18 package to increase the surface area and improve heat dissipation efficiency.

● Use Forced Cooling: In situations where higher heat dissipation is needed, employ forced cooling methods, such as fans or liquid cooling.

Regular Inspection:

● Regularly Measure Voltage and Current: Periodically measure the voltage and current in the circuit where the MM1W18 is used to check if it is operating within normal parameters.

● Observe Physical Changes: Inspect the MM1W18 for signs of damage, such as cracks, discoloration, or other abnormalities, which could indicate potential failure.

● Record Operating Environment: Keep track of environmental parameters like temperature and humidity to facilitate analysis and troubleshooting in case of failures.

Implement Redundancy Design:

● Parallel Usage: In critical circuits, consider using multiple MM1W18 Zener diodes in parallel to improve reliability and stability. If one MM1W18 fails, the others will continue to function.

● Backup Power Supply: For applications requiring high reliability, design a backup power supply system that automatically switches to a backup when the primary power source fails, protecting the circuit from damage.

These fault prevention measures ensure that the MM1W18 operates efficiently and reliably in a wide range of applications, enhancing the performance and longevity of electronic circuits.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd