Service hotline

+86 0755-83044319

release time:2024-11-26Author source:SlkorBrowse:5767

Q: Why is a Zener diode necessary in electronic engineering?

A: A Zener diode, such as the BZX584B15, acts as a stabilizer in a circuit. It ensures that the output voltage remains constant even during voltage fluctuations, protecting the circuit from damage and improving the system's stability and reliability.

Slkor Voltage Regulator Diode BZX584B15 product photo

Q: What is the Zener voltage of the BZX584B15?

A: The Zener voltage of the BZX584B15 is 15V, with a regulation range between 14.7V and 15.3V. This wide and precise range meets the needs of various circuits.

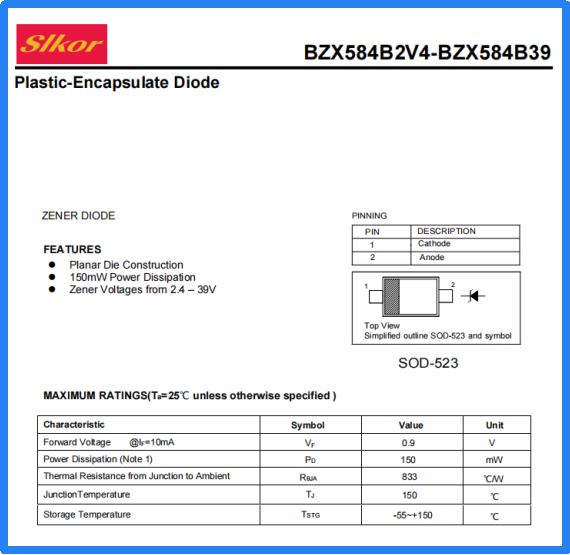

Slkor Voltage Regulator Diode BZX584B15 specification

Q: What are the power rating and reverse current of the BZX584B15?

A: The BZX584B15 has a power handling capability of 150mW, allowing it to efficiently handle significant power without compromising circuit performance. Its reverse current is only 0.1µA, minimizing energy loss and enhancing the circuit's reliability.

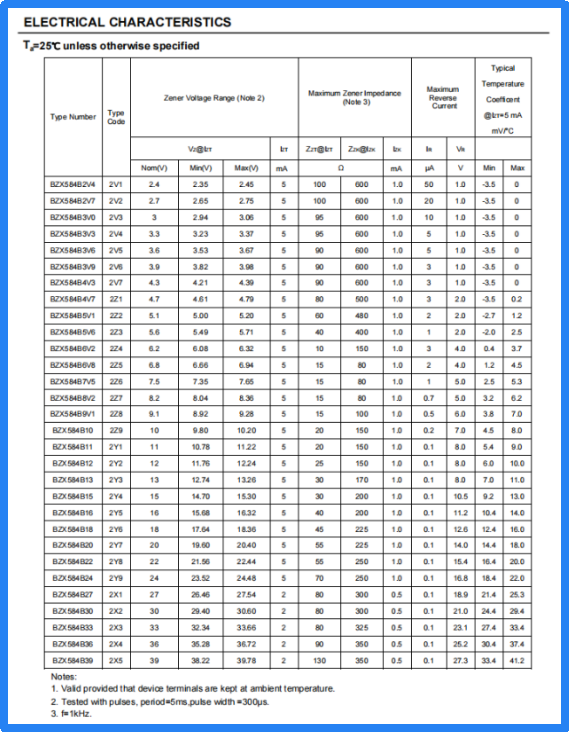

Parameters of Slkor Voltage Regulator Diode BZX584B15

(The following table is for illustration; actual data may differ.)

| Parameter | Value |

| Model | BZX584B15 |

| Zener Voltage (Nominal) | 15V |

| Zener Voltage Range | 14.7V - 15.3V |

| Power Rating | 150mW |

| Reverse Current (Ir) | 0.1µA |

On a smart manufacturing production line, there is a high-precision CNC machine tool. The control system of this machine requires extremely stable voltage; even the slightest voltage fluctuation could reduce machining accuracy or even damage the equipment. However, the factory’s power grid is unstable and frequently experiences fluctuations. To address this issue, the engineers chose the BZX584B15 Zener diode as the voltage stabilizer for the CNC machine's control system.

After installing the BZX584B15, the control system never experienced failures due to voltage fluctuations. Thanks to its precise voltage regulation, high power handling, and very low reverse current, the BZX584B15 ensured stable operation of the CNC system, improving machining accuracy and production efficiency. The engineers praised the BZX584B15, calling it "the strong backbone of circuit stability."

Impact of High Reverse Current on Zener Diode Performance

When evaluating the performance of Zener diodes, reverse current is a critical parameter. The magnitude of reverse current directly affects power consumption, stability, and reliability. This section will explore the specific impacts of high reverse current on Zener diode performance, providing valuable insights for industry professionals.

Increased Power Consumption

Reverse current is the current that flows through the Zener diode when it is in reverse breakdown. As reverse current increases, the Zener diode will consume more power. According to Joule’s law, power consumption (P) is the product of the square of the current (I) and resistance (R), i.e., P = I²R. Therefore, an increase in reverse current will directly lead to higher power consumption.

Higher power consumption means the Zener diode will generate more heat during operation. If this heat is not dissipated in time, the diode’s temperature will rise. High temperatures can accelerate the degradation of the materials inside the diode, reducing its performance and lifespan.

Decreased Stability

The stability of a Zener diode refers to its ability to maintain a constant output voltage under various working conditions. An increase in reverse current will directly affect the diode’s stability.

On one hand, higher reverse current can alter the breakdown voltage. The breakdown voltage is the voltage at which the Zener diode enters reverse breakdown. As reverse current increases, the breakdown voltage may decrease, causing the diode to enter reverse breakdown at a lower voltage, leading to voltage fluctuations and affecting its stability.

On the other hand, an increase in reverse current may also cause uneven temperature distribution within the Zener diode. This uneven temperature distribution creates thermal stress within the diode's internal materials, which can lead to thermal stress failure. Thermal stress failure is one of the key factors in the deterioration of a Zener diode's performance and its reduced lifespan.

Reduced Reliability

Reliability is a critical indicator of the quality of a Zener diode. Increased reverse current directly impacts the diode’s reliability.

Firstly, higher reverse current accelerates the aging process of the Zener diode's internal materials. Aging leads to a gradual decline in performance, such as lower breakdown voltage and reduced voltage regulation accuracy. This degradation directly impacts the diode’s stability and reliability in circuits.

Secondly, increased reverse current can lead to thermal breakdown, which occurs when the diode cannot withstand excessive current at high temperatures. Thermal breakdown causes the Zener diode to fail, rendering it inoperable.

Lastly, higher reverse current can affect the Zener diode's long-term reliability. Over time, increased reverse current accelerates material fatigue and damage, reducing its reliability over extended periods of use.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd