Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:11649

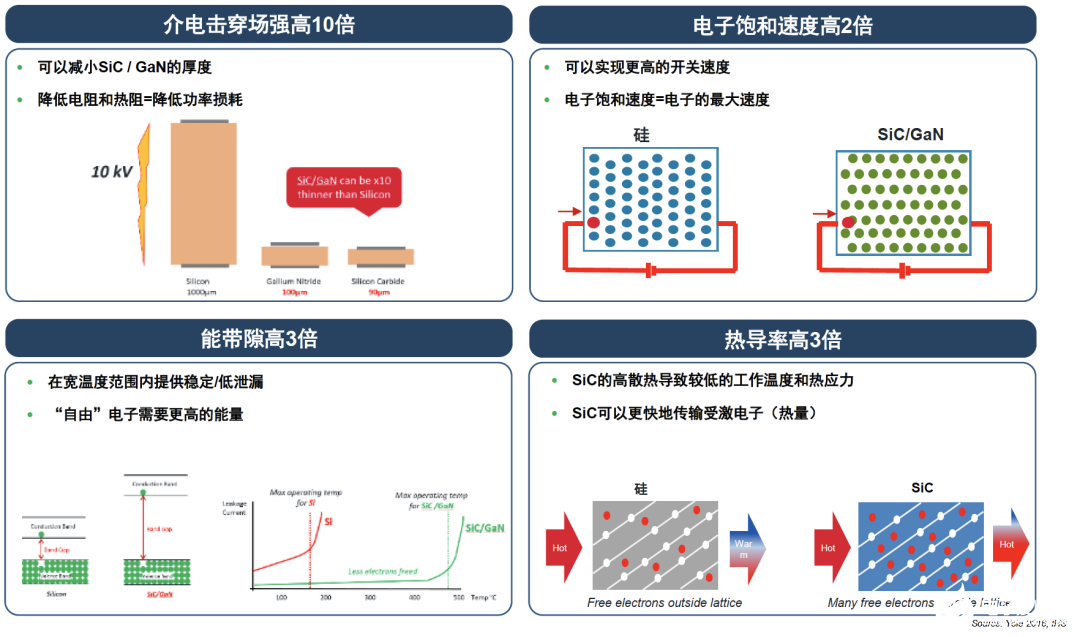

Electricity is developing towards wide bandgap (WBG) materials such as silicon carbide (SiC) and gallium nitride (GaN). Although silicon still dominates the market, SiC and GaN devices will soon give birth to a new generation of more efficient technical solutions.According to Yole Dé, a market research organization headquartered in France; Veloppement estimates that by 2025, the revenue of SiC devices will account for more than 10% of the overall power electronics market, and the revenue of GaN devices will exceed 2%.Well-known suppliers of SiC components include stmicroelectronics (ST), Cree/Wolfspeed, Roma, Infineon, On Semiconductor and Mitsubishi Electric.Cree introduced the first commercial 900V SiC power MOSFET and Wolfspeed 650V SiC MOSFET portfolio; Microchip and ROHM have both released SiC MOSFET and diode; Feiling has introduced eight 650V CoolSiC MOSFET devices. 。 .。 。 It can be seen from this that all major manufacturers have their own layout and development strategies in SiC materials.What is the performance advantage of silicon carbide over silicon?Silicon has long been the key semiconductor material in most electronic applications, but compared with SiC, it is inefficient. Nowadays, SiC has been adopted by many applications, especially electric vehicles, to meet the energy and cost challenges of developing high-efficiency and high-power devices.SiC is composed of pure silicon and carbon. Compared with silicon, SiC has three advantages: higher critical avalanche breakdown field strength, higher thermal conductivity and wider band gap.SiC has a wide band gap of 3 electron volts (eV), and can withstand a voltage gradient 8 times larger than that of silicon without avalanche breakdown. The wider the band gap, the smaller the leakage current at high temperature and the higher the efficiency. The greater the thermal conductivity, the higher the current density.

Figure 1: Performance advantages of silicon carbide compared with silicon

SiC substrate has a higher electric field strength, so a thinner base structure can be used, and its thickness may be only one tenth of that of silicon epitaxial layer. In addition, the doping concentration of SiC is 2 times higher than that of silicon, so the surface resistance of the device is reduced, and the conduction loss is also significantly reduced.SiC has been recognized as a technology that can reliably replace silicon. Many manufacturers of power modules and power inverters have planned to use SiC technology in their future product roadmaps.This wide band gap technology greatly reduces switching loss and conduction loss under specific loads, improves heat dissipation management, and provides unprecedented energy efficiency. In power electronic system, heat dissipation design is very important, which can ensure high energy density and reduce circuit size. In these applications, SiC is an ideal semiconductor material because its thermal conductivity is three times that of silicon semiconductor.SiC technology is suitable for projects with high power, such as motors, drivers and inverters. Electric driver manufacturers are developing new driving circuits to meet the converter's demand for higher switching frequency, and adopting more complex and ingenious topology to reduce electromagnetic interference (EMI).SiC devices require fewer external components, more reliable system layout and lower manufacturing cost. With higher efficiency, smaller overall size and lighter weight, the cooling requirements of intelligent design are correspondingly reduced.Application of silicon carbide

Electric car/hybrid car

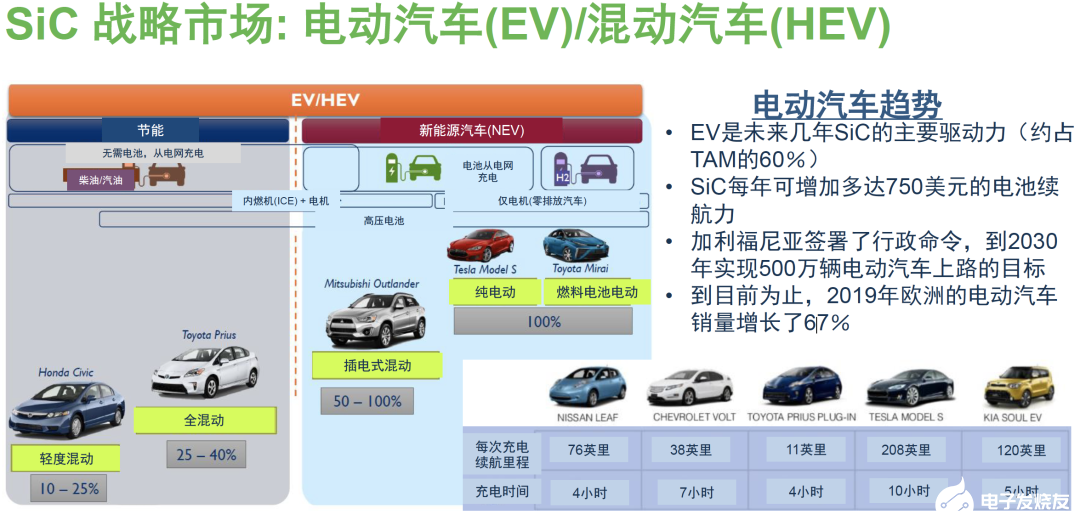

Several automobile manufacturers have taken the lead in introducing hybrid and electric vehicles in the market by using new power concepts. These vehicles contain new devices and systems, such as frequency converters (up to 300kW) for powering engines, 3.6kW to 22kW vehicle battery chargers, 3.6 kW to 22kW induction chargers (wireless charging), DC/DC converters up to 5kW, and inverters for auxiliary loads such as air conditioners and power steering systems.High-voltage battery is one of the main obstacles to the development of hybrid and electric vehicles. Using SiC, automobile manufacturers can reduce the battery size and the total cost of electric vehicles.In addition, because SiC has good heat dissipation performance, manufacturers can also reduce the cost of cooling powertrain devices. This helps to reduce the weight and cost of electric vehicles.Electric vehicle/hybrid vehicle is also one of the SiC strategic key markets of Anson Semiconductor. At the online media exchange meeting of "Anson Semiconductor Silicon Carbide Strategy and Scheme" held recently, Wang Limin, product marketing manager of the company's power supply scheme department, said,Electric vehicle is one of the main driving forces of silicon carbide, accounting for about 60% of the total silicon carbide market capacity. Silicon carbide devices used in main drive, OBC and DC-DC can greatly improve the efficiency, so it can increase the endurance of electric vehicles. Based on these advantages, at present, almost all the manufacturers of main drive inverter take silicon carbide as the main drive direction.

Figure 2: Electric vehicle is one of the main driving forces of silicon carbide.

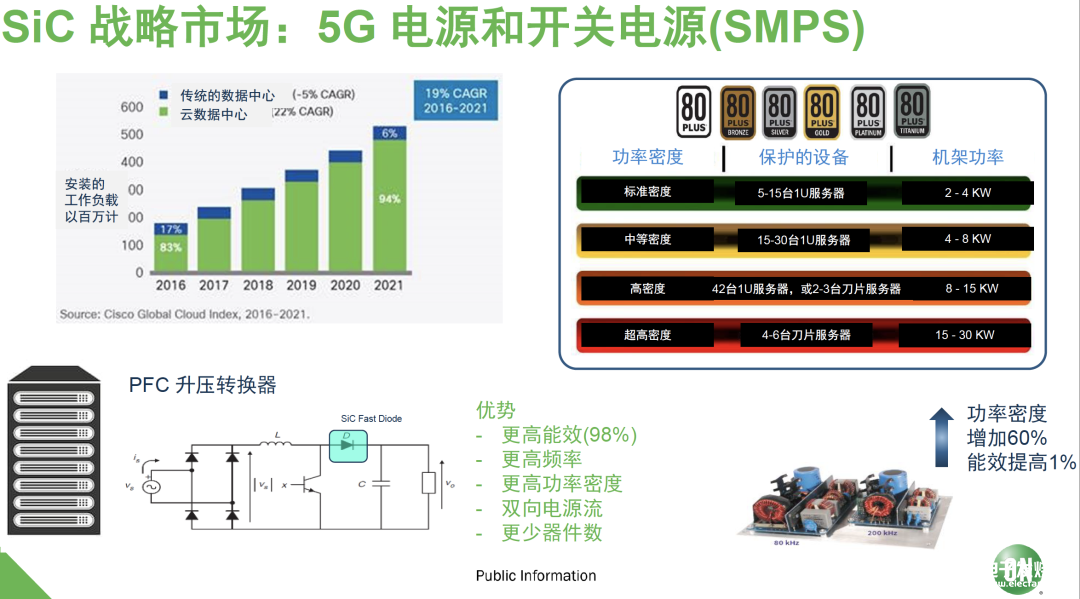

The vehicle charger contains various power conversion devices, such as diodes and MOSFET. Its goal is to make the volume of power electronic circuits smaller by using small-sized passive components, so as to integrate them all together.This goal can be achieved if the semiconductor devices used can be controlled in the same circuit with high switching frequency. However, due to the poor heat dissipation performance of silicon, the high switching frequency solution is not suitable. SiC MOSFET provides an ideal solution for such applications.At present, most OBC and DC-DC manufacturers use silicon carbide devices as high efficiency, high voltage and high frequency power devices.Wang Limin, for example,California has signed an executive order to achieve the goal of 5 million electric vehicles on the road by 2030;Europe also has a timetable for all electric vehicles to replace fuel vehicles;In China's major first-tier cities, electric vehicles can be licensed for free.All these policies have promoted the substantial growth of electric vehicles, and the demand of electric vehicles for high voltage, high frequency and high efficiency devices has also promoted the substantial growth of silicon carbide market.5G power supply and switching power supplyThe 5G power supply and switching power supply (SMPS) field is the second strategic market of silicon carbide for Anson Semiconductor.The traditional switching power supply field is Boost and high-voltage power supply, which has always had high requirements for power density. From the earliest gold standard and silver standard of communication power supply to the current 5G communication power supply and cloud data center power supply, these all have high requirements for high energy efficiency."Silicon carbide devices have no reverse recovery, which makes the power supply energy efficient, which can reach 98%. And 5G power supply are the most traditional and relatively large market of silicon carbide devices at present. " Wang Limin said.

Figure 3: Silicon carbide can be used in 5G power supply and switching power supply.

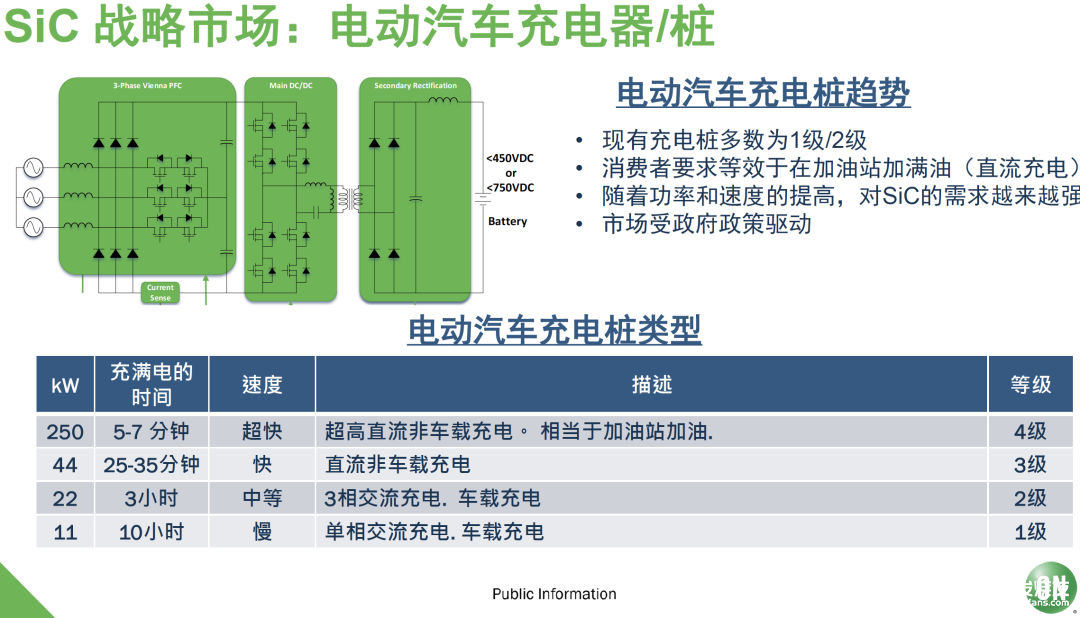

Electric vehicle charging pileElectric vehicle charging pile is also one of our strategic markets for silicon carbide. There are many schemes for charging piles, and now consumers are most interested in DC fast charging.The charging pile with fast DC charging needs very large charging power and very high charging efficiency, all of which need to be realized by high voltage.In the application of electric vehicle charging pile, whether silicon carbide is in Boost or output diode, there are many charging pile schemes of silicon carbide MOSFET using the main switch, and their application prospects are very broad.

Figure 4: Electric vehicle charging pile is also an application field of silicon carbide.

Solar inverter

In the field of solar inverter, the usage of silicon carbide diode is also very large. The installation of solar inverters keeps increasing every year, and it is estimated that 15% of energy (currently 1%) will come from solar energy in the next 10~15 years. Solar energy is free and inexhaustible. Domestic policies have been introduced, and individuals can sell solar power to the state grid."Silicon carbide semiconductor can be applied to Boost of solar inverter. With the optimization of solar inverter cost, many manufacturers will use silicon carbide MOSFET as the main inverter device to replace the original three-level (inverter) control complex circuit. " Wang Limin said, "In terms of policy driving, the EU has a 20-20-20 target, that is, by 2020, energy efficiency will be increased by 20%, carbon dioxide emissions will be reduced by 20%, and renewable energy will reach 20%. NEA has also set a clean energy target to meet 20% of China's energy demand by 2030. "

Figure 5: Application of Silicon Carbide in Solar Inverter

tag

Long-term reliability has become the symbol of SiC MOSFET. The next task of semiconductor manufacturers is to develop multi-chip power modules or hybrid modules, integrating traditional silicon transistors and SiC diodes on the same physical device. With higher breakdown voltage, these modules can work at higher temperature. They can also provide high efficiency while further reducing the size of equipment.From the current market price point of view, SiC MOSFET has a system-level advantage over silicon IGBT. Moreover, with the wide adoption of 150mm wafer manufacturing, it is expected that the price of SiC MOSFET will continue to decline.Some manufacturers have started to produce 200mm (8-inch) wafers. With the increase of wafer size, the cost per die will decrease, but the yield may also decrease. Therefore, manufacturers must constantly improve their processes.However, due to the high manufacturing cost of SiC devices and the lack of mass production, it is difficult to be widely used. The mass production of SiC devices requires a well-designed robust architecture and manufacturing process. For example, in wafer testing, the tested devices are required to be smaller in size and work in a higher current and voltage range.Once these problems are solved, OEM designers will adopt more SiC devices, make full use of their good electrical characteristics, greatly reduce the system cost and improve the overall efficiency.

Disclaimer: This article is reproduced from "Electronic Enthusiasts". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd