Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:9987

High-frequency induction heating uses the principle of electromagnetic induction to heat the workpiece, and the distribution of its power density in the heated workpiece can be conveniently obtained by the selection of frequency and the reasonable design of induction coil. Due to the restriction of electronic switching elements, the high-frequency induction heating power supply has always adopted the electron tube oscillation structure, which is not only inefficient, bulky, costly, but also dangerous to high voltage.

With the development of power electronic devices, MOSFET, IGBT, SiC and other new switching devices appear one after another, which provide the component foundation for miniaturization and high efficiency of high-frequency induction heating power supply. SiC MOSFET is the most promising semiconductor device of high frequency induction heating power supply because of its high operating frequency, low conduction and low switching loss.

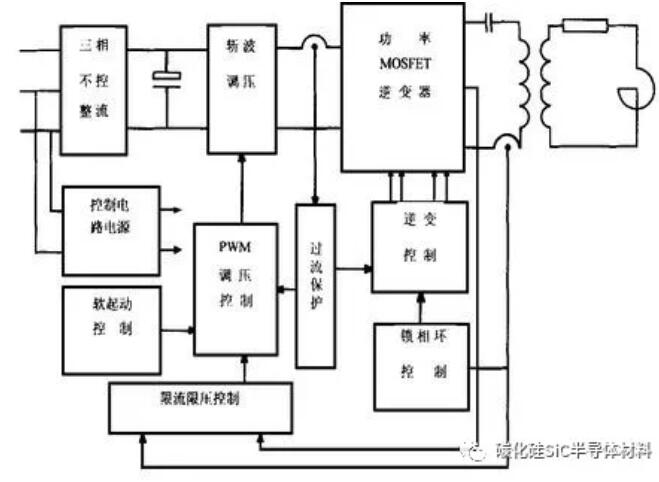

Figure 1: Principle block diagram of high frequency induction heating power supply

Figure 1 shows the principle block diagram of high frequency induction heating power supply, in which the switching frequency of power module used in power inverter circuit determines the efficiency and volume of the whole machine. In order to improve the efficiency and reduce the volume of the power supply as much as possible, it is necessary to make the power device operate at a higher switching frequency, while reducing the conduction and switching losses.

The new SiC MOSFET introduced by CREE Company has the advantages of high operating frequency, low conduction loss, etc. It is very suitable for application in induction heating equipment, which can increase the switching frequency, reduce the volume of reactor and capacitor of filter device, and increase the efficiency of the whole machine. Help effective induction heating equipment manufacturers to launch a new generation of high-frequency, high-efficiency and small-volume products.

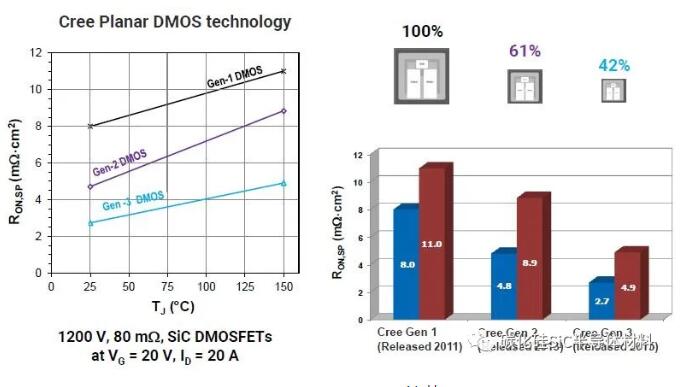

Figure 2: Creesic MOSFET die development

Figure 2 shows that CREE is constantly innovating in the field of SiC. So far, the third generation of SiC MOSFET die has been introduced. Compared with the first generation of die, the area of the latest generation of SiC MOSFET die has been reduced to 42%, thus greatly reducing the conduction impedance and conduction loss.

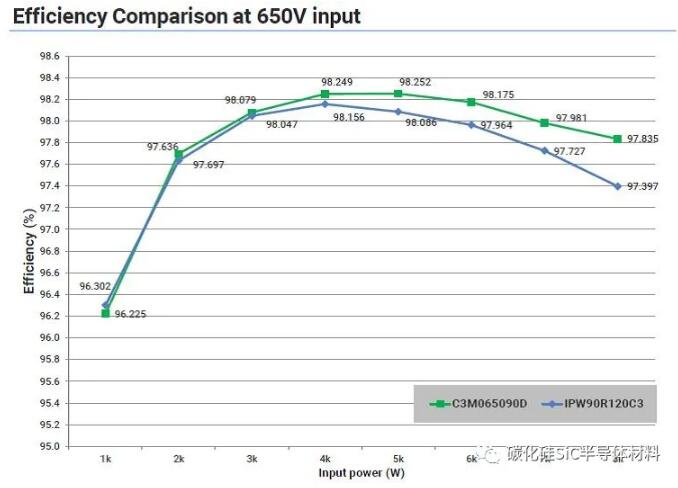

Fig. 3: comparison of SiC MOS and Si MOS efficiency under the same conditions

Fig. 3 shows the efficiency comparison of the prototype tested by using SiC MOS and Si MOS under the same test conditions. It can be seen from the chart that with the constant increase of power, using SiC MOS can significantly improve the efficiency of equipment and reduce the product loss.

Disclaimer: This article is reproduced from "Silicon Carbide SiC Semiconductor Materials". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd