Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:10723

According to statistics, there are 300 million two-wheeled and three-wheeled electric vehicles in the Chinese market. In 2019, the output of electric two-wheeled vehicles in China was 36.09 million, and the sales volume was 34.64 million. Among them, 7 million delivery personnel and 3.1 million couriers were heavy users of electric vehicles. With the official implementation of the new national standard on April 15th, 2019, the sales volume of lithium-ion two-wheeled vehicles in China reached 6.8 million, and the penetration rate of lithium batteries in two-wheeled electric vehicles in China reached 18.8%. It is estimated that the penetration rate of lithium-ion two-wheeled vehicles will reach 53% in 2023. In the two-wheeled vehicle industry, the replacement of lead-acid batteries by lithium batteries has become an inevitable trend. Especially, a large number of shared electric vehicles and lithium battery replacement services appear in the market, which further promotes a large demand for smart lithium batteries.

Battery management system

BMS is a management system for lithium batteries of electric vehicles. When lithium batteries are produced in large quantities, it is difficult to master their quality. In addition, factors such as operating environment, aging, overcharge, overdischarge, etc. make the efficiency and life of the batteries worse, which may lead to safety problems such as fire and burning. In recent years, there have been frequent incidents of charging fires of two-wheeled electric vehicles in cities, and people's demand for battery endurance and battery safety continues to grow. Battery management system BMS is paid more and more attention, and the market will continue to increase. It is estimated that the domestic market of BMS will exceed 50 billion in 2025.

Source: public information collation.

Smart lithium batteries for sharing electric vehicles or changing electricity have special requirements for lithium battery BMS. BMS must have communication function, and the SOC of lithium battery must be calculated accurately, so that the platform or rider can know the available power and make corresponding operations. This is greatly different from the previous mode of estimating power solely by voltage of lead-acid batteries or low-end lithium batteries, which poses a huge challenge to product development and cost of BMS. It is necessary for lithium battery BMS to have powerful functions and reduce costs at the same time. Trillion Innovation and Ruiqi Intelligent jointly solved this problem innovatively, and launched a low-cost and high-performance BMS solution based on GD32E230 MCU chip to promote industrial transformation and development.

Overview of BMS scheme

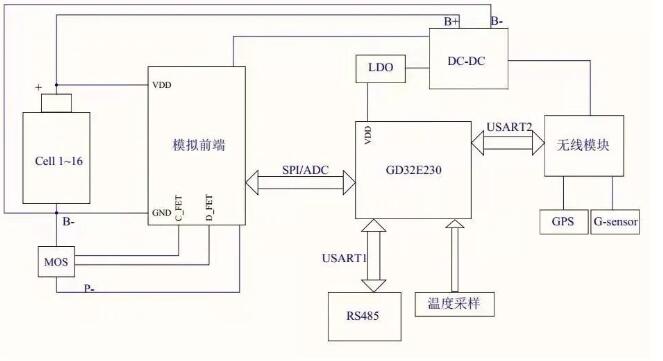

✔ The BMS solution developed by Rui Intelligent based on GD32E230 MCU chip is mainly suitable for the management of 16 strings of lithium batteries, which can provide overcharge, overdischarge, overcurrent, over-temperature, under-temperature and short-circuit protection functions for lithium battery packs, and also provide the voltage equalization function during charging; It can communicate with PC host computer, cabinet controller, etc. through RS485, and can control, calibrate and monitor the equipment through the host computer software.

✔ This solution is equipped with 4G wireless communication module, which can upload the monitoring information of battery pack to the monitoring background. It can perform high-precision GPS (compatible with GPS and Beidou) positioning and remote wireless OTA upgrade.

✔ Through the bottom-level development and innovative design based on the chip, this scheme greatly improves the integration of the products of the scheme. Compared with similar products on the market, the number of devices is reduced by more than 30%, and the Layout area is greatly reduced, so the PCB size can be designed more flexibly to meet the installation size requirements of lithium battery PACK.

BMS scheme system block diagram

BMS方案技术参数表

|

项目 |

常规参数 |

备注 |

|

产品名称 |

电池管理系统BMS |

以16串磷酸铁锂 电芯为例 |

|

产品型号 |

RK4640-4824-1.536KWh |

|

|

额定容量 |

上海24000mAh |

0.5C标准充电后0.2C标准放电, 25±2℃环境下 |

|

标称电压 |

51.2V |

3.2V/CELL |

|

标准充 电电压 |

57.6V |

CC-CV 模式 |

|

标准充 电电流 |

10A |

Ta= 25±3℃ |

|

[敏感词]充 电电流 |

13A |

充电环境温度25±3℃ |

|

充满条件 |

使用57.6V / 10000mA(CC-CV)持续充电至充[敏感词]芯电芯3600MV |

充电时间:大约2.5个小时 |

|

正常工作 放电电流 |

20A |

CC-CV 模式 |

|

[敏感词]放 电电流 |

50A |

客户系统控制器规格限制<40A |

|

放电终 止电压 |

43.2V |

当单颗电芯的电压降到2.7V时停止放电 |

|

静态功耗 |

≤ 2mA |

|

|

工作温 度范围 |

充电: -5~60℃ |

|

|

放电: -20~60℃ |

Introduction of BMS solution components

1

The function of GD32E230 MCU in this scheme

Comply with VITA46.11 specification.

Support HPM.1 firmware upgrade

Provide FRU and SDR editing software

Analog input voltage, current, temperature, etc

Temperature measurement and payload communication

Hot-swap input, LED and payload power control output

2

Main specifications of GD32E230 series MCU

Cortex-M23@72MHz

Flash:16KB~64KB

SRAM:4KB/8KB

Multiple communication modes:I2C x2,SPI x2,UART x2

High-speed and high-precision ADC,12bits ADCx1@2.6Msps,16 channels

Advanced timer x1 can generate 6 complementary PWM outputs with adjustable dead time.

General timer x5

GFlash patented encryption technology

Rich package types: LGA20/TSSOP20/QFN28/QFN32/LQFP32/LQFP48

supply voltage:1.8V~3.6V

Operating temperature range of industrial grade:-40℃-+85℃

BMS scheme circuit board physical drawing

BMSProgram characteristics

Working temperature:-40℃~+85℃;

Supports up to 16 strings of batteries.;

Support overvoltage, undervoltage, overcurrent, overtemperature, low temperature, short circuit protection, etc.;

Support accurate SOC measurement;

Support equilibrium;

Support 485 communication;

Support 4G communication module expansion interface, customers can realize 4G communication and GPS positioning function according to the demand of lithium battery products.;

Sampling temperature: 2 channels of cell temperature and 1 channel of MOS temperature.;

✔ This scheme has high integration, low cost and strong cost competitive advantage.This scheme adopts the industry's smallest Layout board area, which can adapt to any challenging lithium battery PACK design. At the same time, it is compatible with 4G IoT interface design, and the product is easy to upgrade to IoT BMS. We provide a complete reference design scheme, configuration tools and production tools, which can quickly ensure the mass production of products and greatly reduce the investment in product research and development.

Disclaimer: This article is reproduced from "GD32MCU". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd