Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:11093

Advance SiC electrification by going up one flight of stairsHow will our semiconductors improve the performance of automobiles and other industries in the future?John Palmour, Chief Technology Officer of Wolfspeed of Cree Company

Many power supply systems are changing from silicon (Si) technology to silicon carbide (SiC) technology. This will be the biggest change experienced by the power semiconductor industry since the bipolar semiconductor changed to insulated gate bipolar transistor (IGBT) in 1980s. At the same time of this transformation, many industries affected by it are also experiencing an unusual period of comprehensive transformation. From automobile industry to solar energy, the advantages of silicon carbide (SiC) have become noticeable. While undergoing great changes, all major manufacturers are making efforts to further integrate silicon carbide (SiC) into their own technologies.

Automobile industry is a typical example of unprecedented changes in modern industry. In the next decade, the automobile industry will change from internal combustion engine to electrification. The transformation from silicon (Si) to silicon carbide (SiC) plays an important role in helping electric vehicles meet the needs of consumers, and at the same time, it can meet the government regulations on the impact of climate change. Silicon carbide (SiC) solutions are helping electric vehicles "by going up one flight of stairs", upgrading applications such as fast charging infrastructure, drive inverter and power supply, and promoting the progress of telecommunications, and aerospace applications.

Figure 1. Cree employees in the laboratory

Electric vehicle opportunity

With the increasing consumer demand and the strengthening of government regulations, automobile manufacturers such as Tesla, Ford and Volkswagen announced that they would invest more than $300 billion in electric vehicles in the next decade. Analysts predict that by 2030, the number of pure electric vehicles (BEV) will reach 15% of the total number of automobiles. Therefore, in the next few years, the market of silicon carbide (SiC) components for electric vehicles will increase exponentially.

Electrification is so important that manufacturers can no longer turn a blind eye to the advantages of silicon carbide (SiC). Compared with silicon (Si) technology used in traditional electric vehicles, silicon carbide (SiC) can increase the battery life, improve its performance and shorten the charging time. Therefore, many suppliers have announced their cooperation with Cree to develop electric vehicle plans. For example, Delphi Technologies is developing a more efficient, smaller and lighter inverter system using silicon carbide (SiC) semiconductor, while ZF Group is developing an all-electric drive powertrain. ABB Group is developing and providing various power systems using silicon carbide (SiC).

Efficiency improvement

The switching loss of silicon carbide (SiC) is much lower than that of silicon (Si)-based IGBT. In addition, the silicon carbide device has no built-in voltage, and its conduction loss is obviously low. Therefore, silicon carbide (SiC) has higher power density, lighter weight and higher operating frequency. In a recent automobile test, compared with silicon (Si), Cree's silicon carbide (SiC) technology reduced the inverter loss by about 78%.In the automotive sector, these efficiency improvements can be applied to powertrain solutions, power converters, and non-on-board charger and on-board charger. Compared with traditional silicon (Si)-based solutions, silicon carbide (SiC) can improve the overall efficiency of electric vehicles by 5% to 10%. Manufacturers can use this to increase the cruising range or reduce the use of bulky and expensive batteries.

In addition, silicon carbide (SiC) can also reduce the cooling requirements, save space, and its weight is lighter than that of silicon (Si)-based scheme. Silicon carbide (SiC) can also provide support for fast chargers, and the battery life can be increased by 75 miles after charging for 5 minutes at present.

The continuous decrease in the cost of silicon carbide (SiC) solutions has led to a further increase in its adoption rate. Taking automobiles as an example, we estimate that the value of silicon carbide (SiC) components used in an electric vehicle is about $250 to $500 (depending on its power requirements). The total cost saved by automobile manufacturers in terms of battery cost, volume and weight of batteries and inverters, and cooling requirements of each electric vehicle can be as high as $2,000. Although many factors are driving the transformation from silicon (Si) to silicon carbide (SiC), this is the key.

Outside the automobile industry

The demand of automobile industry accounts for about half of Cree's $9 billion opportunity of silicon carbide (SiC), while the fields of solar energy, aerospace, and communication infrastructure are the main drivers of other demands. According to the recent forecast of Canaccord Genuity Company, by 2030, the demand for silicon carbide (SiC) will exceed USD 20 billion.

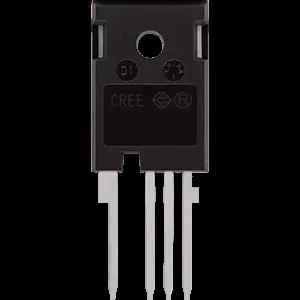

Figure 2. Cree 650V MOSFET

Silicon carbide (SiC) power devices can also help industrial and energy enterprises to maximize the utilization rate of electricity and space. Silicon carbide (SiC) endows high-frequency industrial power supply and uninterruptible power supply with higher efficiency, higher power density and lighter weight. The benefits brought by SiC far exceed its own cost.

In these areas, higher efficiency means higher profits.In the field of power electronics, the efficiency of silicon carbide (SiC) is much higher than that of silicon (Si), and its power density is three times that of silicon (Si), which makes the high-voltage system lighter, smaller, more efficient and more cost-effective. This excellent performance has reached the explosive point, and manufacturers can no longer turn a blind eye to it if they want to remain competitive in the current market.

Semiconductor future

Cost is the main obstacle to the adoption of silicon carbide (SiC). However, with the continuous improvement of output and experience, its cost is also decreasing. Therefore, its manufacture becomes more efficient and refined. More importantly, customers have come to realize that the real value of silicon carbide (SiC) lies in the system level, rather than the device level comparison. In order to meet the needs of various industries, the manufacturing of silicon carbide (SiC) will be further promoted, and the output will continue to increase, thus its price will continue to decline. Taking Cree as a reference, Cree has made a large-scale investment in order to meet these demands, including the construction of a factory in New York State that adopts cutting-edge technology and meets the standards of vehicle regulations, which will increase the production capacity to more than 30 times that of 2017.

The transformation from silicon (Si) to silicon carbide (SiC) is no longer a question of whether and when it will happen. We are already in it. It is exciting to fully participate in the great changes of many industries. The future of these industries will never be static, and we will certainly continue to see unprecedented changes. And those manufacturers who can quickly adapt to these changes will surely reap fruitful results.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd