Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:11204

Recently, power electronics is very popular. Here, I'll sort out some viewpoints of several materials.

2022 is a very important year for the use of silicon carbide in China, mainly because the current 800V system has brought many changes.What are the differences from different levels? I want to discuss them with you according to the combing materials.

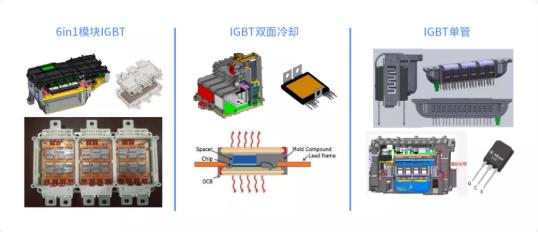

First of all, let's talk about IGBT. In fact, in the field of electric vehicles, we would like to thank Infineon in particular. Before European automobile companies came in, Nissan, Honda and Toyota all developed inverters around their own technologies, and took the cooling and iterative technology of IGBT as the core; Before Tesla introduced SIC, it also used single-tube IGBT for high-power drive. After Infineon made IGBT with standard package 6in1, the difficulty of inverter development was greatly reduced.

▲Figure 1. Several usages of 1.IGBT

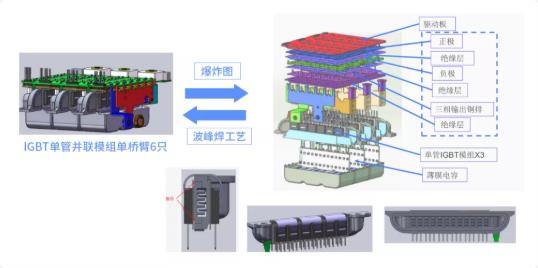

In the design of high-power inverter, Tesla's engineers adopted discrete single-tube parallel connection, built-in single-tube heat dissipation and cooling technology, and power laminated bus technology, which increased the power of this device, but the assembly process was quite complicated.

▲Figure 2. Design of Tesla Single-tube IGBT

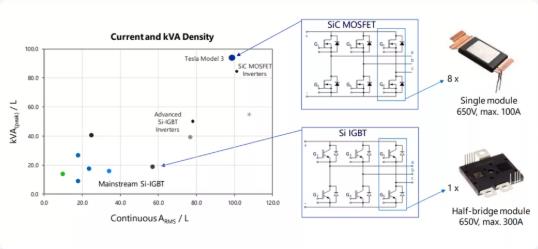

Therefore, in the iteration, Tesla was the first to directly iterate into SiC in 400V products. According to the data reference given by Cree, as shown in the following figure:

Power and efficiency:

▲Fig. 3. if SiC and IGBT are compared according to power and current density

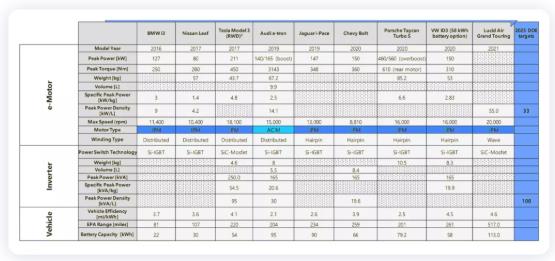

Of course, judging from the efficiency of the inverter itself, the benchmark is mainly based on the parameter specifications:

▲1. Comparison of motor, inverter and vehicle parameters

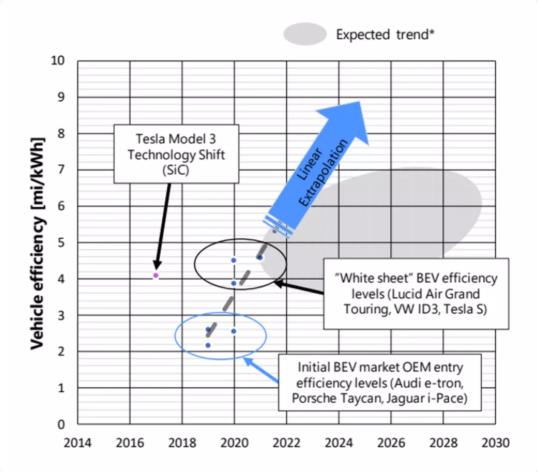

That is to say, the efficiency brought by 400VSiC will be caught up by many subsequent vehicles, and a car like Lucid Air can also achieve a higher Mile/kWh.That is to say, the efficiency brought by 400VSiC will be caught up by many subsequent vehicles, and a car like Lucid Air can also achieve a higher Mile/kWh.

▲Figure 4. Overview of energy efficiency of the whole vehicle according to time

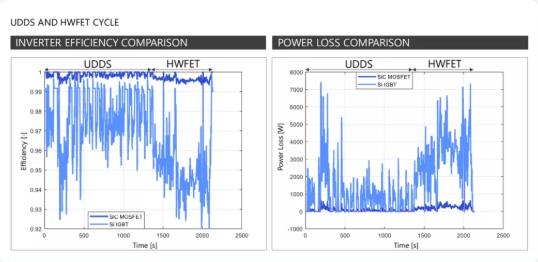

The following figure shows the dynamic characteristics. Compared with the inverter efficiency under UDDS and HWFET, there is still a dynamic difference from here, ranging from 4% to 7%.

Remarks: This data is made by FEV, and abstract data is used for comparison.

▲Figure 5. Efficiency difference between 5.SiC and silicon-based IGBT

That is to say,The simulation level can be compared with the actual test, and there is indeed a big difference in efficiency.。

▲Figure 6. Comparison of 6.SiC Ford

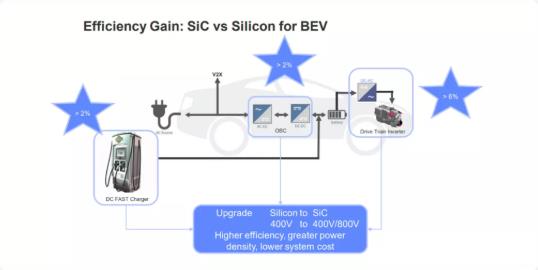

In this sense, 2% is at the charging level, 6% is at the running level, and the efficiency difference between the two systems is 8%-this means that for the same large battery, especially the fast charging battery of 100-120kWh, according to the efficiency of 8%, the net income of the battery can be weighted to 8-10kWh; According to 0.8 yuan /Wh, the corresponding value is about 6,400-8,000 yuan.

In the long run, it is not only the cost benefit, but also the support of SiC is necessary for large-capacity batteries to achieve high endurance and high efficiency.

▲Figure 7. Efficiency Difference of Silicon Carbide

Disclaimer: This article is reproduced from "Automotive Electronic Design". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd