Service hotline

+86 0755-83044319

release time:2025-01-07Author source:SlkorBrowse:4816

In today’s fast-paced electronic industry, the transient voltage suppressor (TVS) diode plays an indispensable role in protecting circuits from transient voltage surges. Among these, the SMAJ40CA stands out as a high-performance TVS diode, favored for its bidirectional polarity, precise reverse working voltage, and breakdown voltage characteristics, making it a preferred choice in numerous circuit designs. This article explores the technical features of the SMAJ40CA diode and, in conjunction with the technological evolution of Apple’s A-series smartphone processors, examines the broader trends in the development of the electronics industry.

Slkor Transient Protection Diode SMAJ40CA product photo

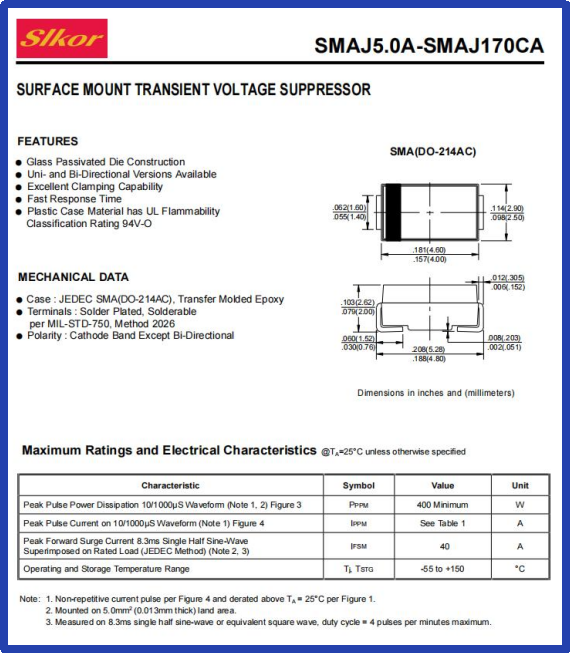

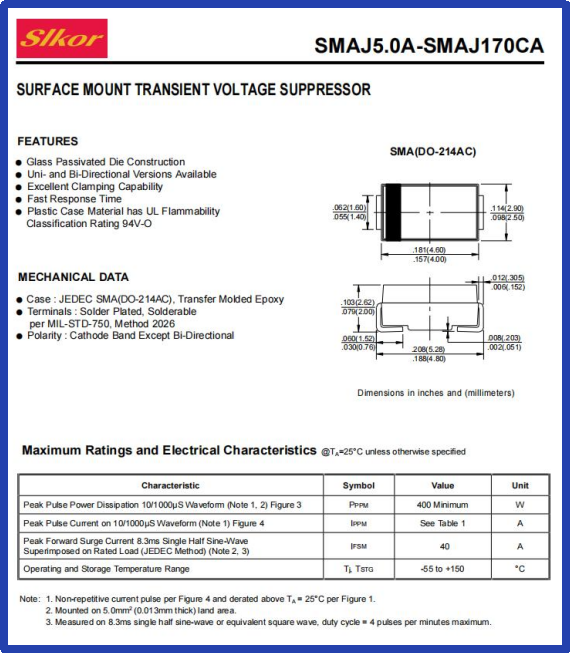

The SMAJ40CA is a bidirectional transient voltage suppressor diode, meaning it can provide effective protection against both positive and negative voltage anomalies. It has a reverse working voltage (Vrwm) of 40V, which ensures that the diode remains non-conductive as long as the circuit voltage stays below this threshold. When the voltage exceeds this level, the SMAJ40CA’s breakdown voltage range (minimum 44.4V, maximum 49.1V) activates, allowing the diode to conduct and clamp the voltage to a safe level, with a maximum clamping voltage of 64.5V. This rapid voltage suppression prevents potential damage caused by voltage transients. Additionally, its reverse leakage current (Ir) is only 5μA, ensuring extremely low power consumption at low voltages, which is crucial for extending battery life and enhancing overall system efficiency.

Slkor Transient Protection Diode SMAJ40CA specification

Parameters of Slkor Transient Protection Diode SMAJ40CA

Meanwhile, Apple’s A-series smartphone processors have undergone unprecedented technological advancements since the launch of the A7 chip in 2013. From the initial 28nm process, to the A18 Pro chip with its 3nm process in 2024, Apple has not only increased the core count from quad-core to multi-core designs, but also dramatically boosted transistor density, from 1 billion in the A7 to 20 billion in the A18 Pro. This leap has resulted in significant improvements in computing performance, while also advancing energy efficiency, AI processing, and graphics rendering capabilities.

However, each step forward in process technology comes with a sharp rise in manufacturing costs. According to a report by Ben Bajarin, CEO and chief analyst at Creative Strategies, as transistor counts skyrocketed, the price of wafers surged from $5,000 in the A7 era to $18,000 for the A17 and A18 Pro. The cost per square millimeter also increased from $0.07 to $0.25. This escalating cost not only challenges Apple’s cost control efforts but also poses a broader challenge to the semiconductor industry.

The story of the SMAJ40CA and Apple’s A-series processors represents the ongoing balancing act between technological progress and cost control in the electronics industry. On one hand, the SMAJ40CA diode provides robust transient voltage suppression, ensuring the stable operation of electronic devices and highlighting the importance of technological innovation in enhancing product reliability and longevity. On the other hand, the evolution of Apple’s A-series processors demonstrates the immense market potential and user value driven by technological progress, while also revealing that as process precision improves, cost control becomes a crucial factor in the widespread adoption of these advancements.

In conclusion, whether it’s a foundational component like the SMAJ40CA or a high-end processor like Apple’s A-series, their development reflects the broader trend in the electronics industry of striving for higher performance and lower power consumption while confronting the challenges of manufacturing costs. Moving forward, how to maintain technological leadership while effectively controlling costs will be a common challenge for all players in the electronics sector. With ongoing advancements in materials science and manufacturing processes, we are optimistic that the industry will navigate this balancing act with increasing success, providing a more solid foundation for the digital transformation of society.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd