Service hotline

+86 0755-83044319

release time:2022-03-17Author source:SlkorBrowse:11178

In the manufacturing process of printed circuit board, the quality of welding will directly affect the quality of the whole product. Common solderability problems include: poor wetting, erection of monuments, cracks, air holes, false welding, virtual welding, poor tin plating and slag inclusion, etc.

What is the reason for this kind of welding failure?

This involves the following aspects:

01

Whether the quality of raw materials such as flux and solder meets the requirements. The performance and quality of raw materials affect the weldability of products.

02

Influence of welding process. Such as the control of time and temperature, usually the higher the temperature, the better the wettability, and the length of time will affect the formation of intermetallic compound structure.

03

Whether the quality of components and PCB itself is up to standard. Due to the influence of various environmental factors, the performance and quality of different batches of components will change correspondingly, and the solderability of the whole machine will also be affected by components and PCB boards.

04

The surface coating of the product affects its wettability. The solderability of different coating types is different, and the serious aging of coating will also make the solderability of products worse.So, how can we accurately and efficiently find the root cause of poor solderability of PCB products?

Solderability test is used to evaluate the solderability of components, printed circuit boards, solders and fluxes qualitatively and quantitatively. No matter the obvious poor welding problem, or the problem that is not easy to detect, or will affect the soldering ability of the product, it can be found through testing, and the root cause can be found out, which can help enterprises to efficiently determine the weldability and product quality after production and assembly.

At the same time, with the popularization of lead-free technology, new requirements are put forward for welding materials and welding technology. As a part of quality management system, solderability test naturally becomes necessary!

Therefore, in order to improve the welding quality of products, we need to conduct a scientific solderability test on printed circuit boards!

Therefore, today, the content shared by Maxim Testing Laboratory is the solderability test of printed boards.

First of all, let's take a look at the relevant knowledge points:

solderability

Solderability test, English is "Solderability". Generally, the solderability of components, PCB, PAD, solder and flux is evaluated quantitatively and qualitatively by the method of wetting balance.

In modern electronic industry, IC packaging, electronic components assembly to printed circuit boards and other processes all need high-quality interconnection technology, and at the same time, high-quality and zero-defect welding technology is constantly required, so the solderability test becomes increasingly prominent.

(Source: Baidu Encyclopedia)

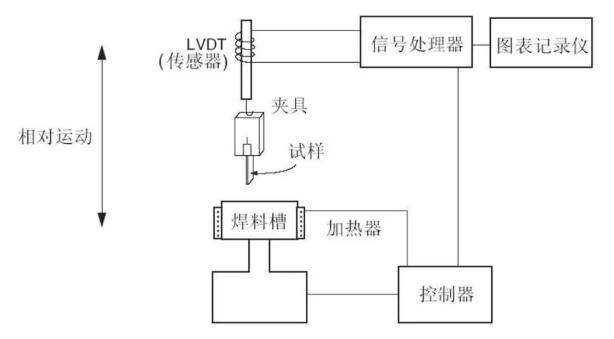

Its principle is to sense the tiny force through the sensor, and judge the strength of tin climbing and wetting speed by combining time. Specifically, the sample is placed on the fixture, stably connected to the sensor through the fixture, and dipped into the solder paste at the set temperature. During this period, the data such as force and time are transmitted to the PC through the sensor, and curves and data files are formed through software, so as to accurately and quantitatively evaluate the solderability of the sample.

Solderability test method

International standards organizations IEC, IPC, DIN, JIS, etc. recommend various methods, such as edge immersion welding test, floating welding test, wave welding test, wetting balance test, etc.

Because of its good repeatability and reproducibility, the wetting balance test has become a recognized and recommended solderability test method for qualitative and quantitative analysis. Let's show the wettability balance test of solderability test through a case done by Maxim's Testing Laboratory.

Typical solderability test cases (wetting balance test)The sample received by Maxim's Testing Laboratory is a PCB sample, and it is necessary to test the solderability of a specified position to detect the tin plating capacity of that position.

Testing environment: the ambient temperature is 22.3℃; Humidity 54% R.H.

Testing standard: IPC J-STD-003C PCB solderability test

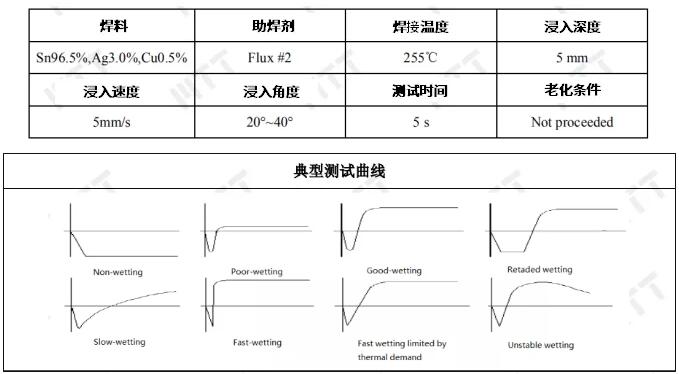

Test conditions:

Detection range:

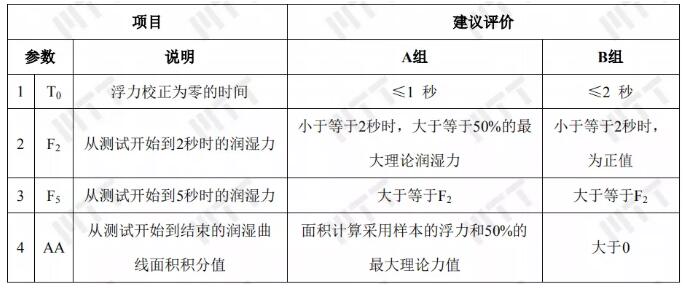

Hint:

01

This suggested standard has been established as a two-tier evaluation format, of which Group A is more stringent. The recommended standard of Group A is more applicable to large-scale welding process than that of Group B. Admittedly, the suggested standards of Group B can also be completely adopted by large-scale welding processes, but this is only when users have determined the best suggested component integration process.

02

F (theoretical value of maximum force) =t· p· cosα-d· g· V (see appendix for details)

03

S (area) = {50% & times; 3.0s×

F (maximum theoretical value)}-(2.0s & times; 0.8× V)

Appendix:

T= surface tension of solder

P= the maximum immersion depth of the sample (in mm)

V= the volume of the sample immersed in the maximum depth (in cubic millimeters)

α = the wetting angle of solder under the best condition, that is,

α=0°

G= acceleration of gravity, i.e. g=9.8m/s²

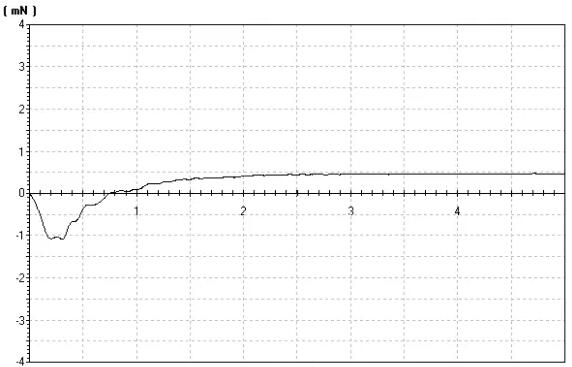

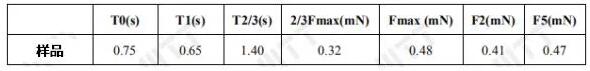

Get the detection curve and data:

(detection curve)

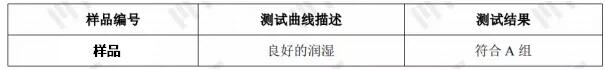

(test data)The final test result.:

Good weldability is the basis to ensure high weldability and reliability, so it is necessary to test the weldability of our products! There are many test standards for solderability test, and Maxim's Testing Laboratory simply lists some of them for your reference:

·J-STD-002B 2003-2 Solderability test of components, lugs and terminals

· J-STD-003B(2007-3) Solderability Test of Printed Circuit Board

· IPC-TM-650 2.4.14 solderability of metal surface

· IPC-TM-650 2.6.8 Thermal stress test

· GB/T 4677 test method for printed boards

· Weldability and thermal stress test of IEC60068-2-58/ IEC60068-2-20

· GB2423.28 basic environmental test code for electrical and electronic products

· GB2423.32 basic environmental test code for electrical and electronic products

· MIL-STD-202G Method 208H weldability test

· MIL-STD-202G Mehtod 210F thermal stress test

· MIL-STD-883G 2003.7 weldability test

Disclaimer: This article is reproduced from "Electronic Production Information Station". This article only represents the author's personal views, and does not represent the views of Sacco Micro and the industry. It is only for reprinting and sharing to support the protection of intellectual property rights. Please indicate the original source and author when reprinting. If there is any infringement, please contact us to delete it.

Company Tel: +86-0755-83044319

Fax/fax:+86-0755-83975897

Email: 1615456225@qq.com

QQ: 3518641314 Manager Li

QQ: 332496225 Manager Qiu

Address: Room 809, Block C, Zhantao Technology Building, No.1079 Minzhi Avenue, Longhua New District, Shenzhen

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd