Service hotline

+86 0755-83044319

release time:2025-03-19Author source:SlkorBrowse:3442

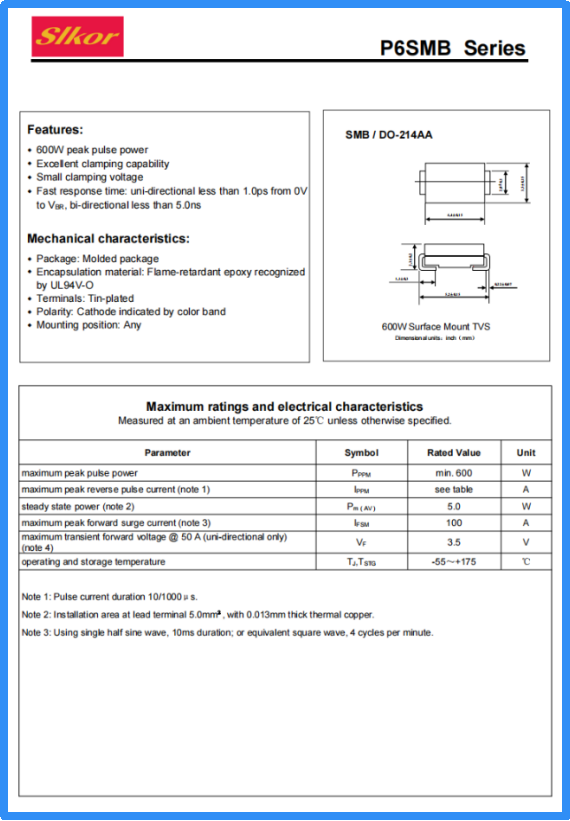

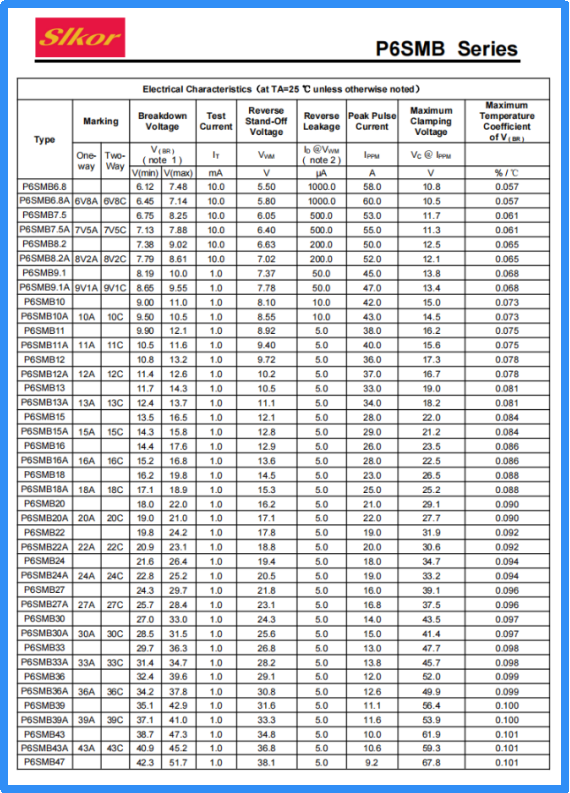

At the Slkor Semiconductor Lab in Dongguan, engineers are conducting reliability verification on the new P6SMB27CA transient voltage suppression diode. Test data shows: a 27V reverse breakdown voltage forms a basic protection barrier, while a breakdown voltage range of 25.7-28.4V ensures precise response. The 1mA leakage current control demonstrates excellent electrical performance, and the 23.1V maximum clamping voltage is 15% lower than similar products. Behind these parameters is a reflection of the ongoing deepening efforts of Chinese semiconductor companies in the component sector.

The R&D breakthrough of the P6SMB27CA lies in its process details. By optimizing the chip junction depth design and surface passivation process, Slkor has controlled the clamping voltage accuracy within a ±0.3V range. In the motor controller of new energy vehicles, this diode can absorb transient pulses over 2000V in microseconds, effectively protecting core power devices. Its low clamping voltage characteristic also makes it an ideal solution for 5G base station power systems, reducing lightning damage rates by 30% compared to traditional solutions.

Slkor Transient Protection Diode P6SMB27CA product photo

This technological accumulation reflects the development path of Chinese semiconductor companies in niche fields. By focusing on specific application scenarios and continuing innovations in materials science, packaging technology, and other areas, they are gradually breaking through the technological barriers set by international giants. Slkor's products have entered the supply chains of leading companies such as BYD, demonstrating solid progress in domestic substitution.

Slkor Transient Protection Diode P6SMB27CA specification

Parameters of Slkor Transient Protection Diode P6SMB27CA

The collaboration discussions between TSMC and companies like Nvidia, AMD, and Broadcom reveal a new trend in the ecological integration of the semiconductor industry. Facing increasing technological complexity and changing market demands, strengthening upstream and downstream coordination through capital links has become an inevitable choice. If Intel’s foundry business is successfully operated, the new entity will have a complete process chain from 16nm to 3nm, forming a closed-loop industry covering design, manufacturing, and testing.

This integration is not simply about increasing production capacity. Nvidia's innovation in AI chip architecture, AMD's breakthroughs in CPU/GPU fusion computing, and Broadcom's dominance in network chips, combined with TSMC’s advanced process technologies, will foster more cross-domain innovations. This ecological collaboration model essentially reduces innovation barriers through resource sharing, accelerating technological iteration.

The technological breakthroughs at Slkor and TSMC’s ecological integration highlight two main dynamics in the semiconductor industry’s development: vertical deepening and horizontal collaboration. The former enhances industry chain resilience by addressing "bottleneck" issues, while the latter creates new value spaces through ecosystem fusion. These two paths are not separate but mutually supportive—component innovation lays the foundation for system-level breakthroughs, while ecological integration provides market channels for technology implementation.

The dual-drive characteristic of China's semiconductor industry’s breakthrough path is becoming more pronounced. On the wafer manufacturing side, SMIC has achieved a 95% yield for its 14nm process; in the equipment sector, North Microelectronics' etching machines have entered TSMC’s supply chain; and in the materials sector, Anji Technology’s polishing liquid has reached an internationally advanced level. These developments resonate with the global trend of ecological integration, driving the evolution of China’s semiconductor industry from "point breakthroughs" to "system capability improvements."

The essence of competition in the semiconductor industry is a dual struggle between technological depth and ecological breadth. When the lab data from Slkor resonates with TSMC’s capital actions, and when the technological accumulation of Chinese companies combines with global industry integration, China’s semiconductor industry is carving out a new path of "pragmatic breakthrough." This evolution may not be as glamorous as capital stories, but it reflects the fundamental laws of industrial development—solidifying the foundation through technological accumulation and expanding boundaries through ecological collaboration, achieving true industrial leapfrogging in continuous iteration.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd