Service hotline

+86 0755-83044319

release time:2025-02-26Author source:SlkorBrowse:3532

In today’s rapidly advancing world of electronics, even the smallest innovations can become powerful drivers of industry progress. The launch of the SMBJ36A Transient Voltage Suppression Diode is a vivid representation of this trend. With its exceptional reverse standoff voltage, precise breakdown voltage control, and ultra-low reverse leakage current, it provides a new solution for circuit protection in electronic devices. At the same time, Intel has announced that ASML's cutting-edge lithography machines have been successfully deployed in its factory, marking a significant leap forward in chip manufacturing.

Slkor Transient Protection Diode SMBJ36A product photo

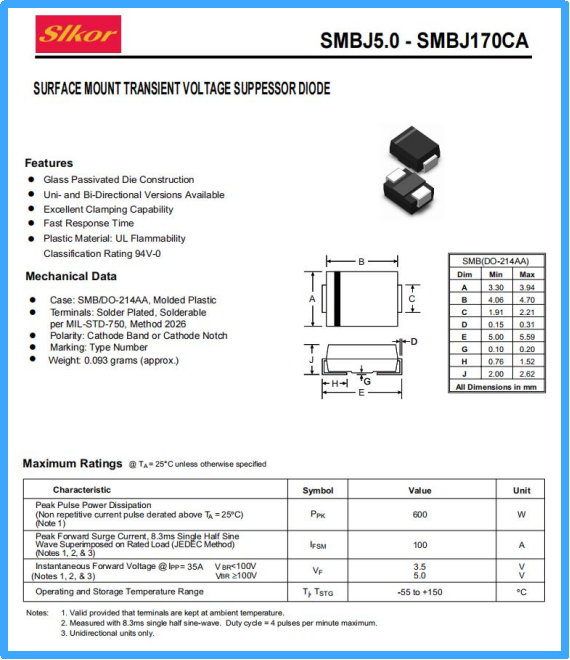

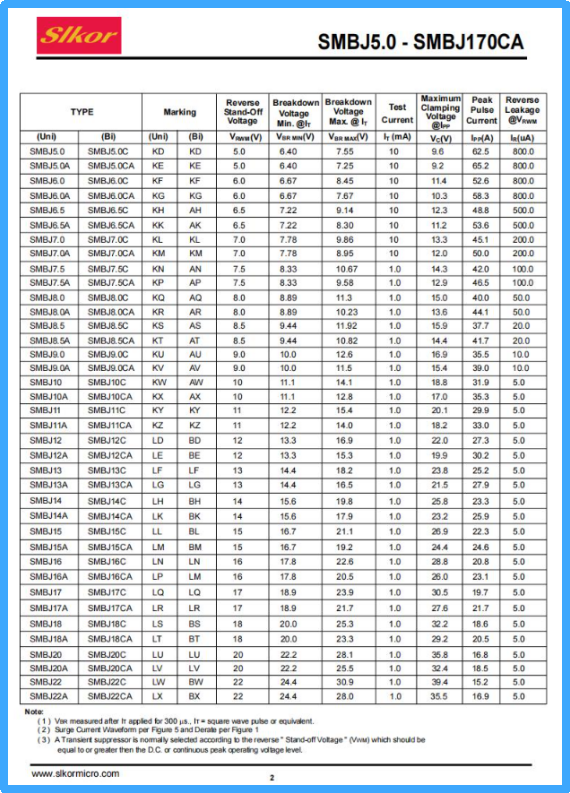

The SMBJ36A diode, with its unique 36V reverse standoff voltage (Vrwm) design, has become a preferred component for high-voltage electronic devices. This feature allows the SMBJ36A to effectively shield circuits from transient overvoltage surges, ensuring normal operation while protecting circuits from external factors like lightning strikes and electrostatic discharge. Its breakdown voltage range is precisely controlled between 40V and 46V, enhancing product reliability and providing greater flexibility and safety for circuit design.

Slkor Transient Protection Diode SMBJ36A specification

Notably, the SMBJ36A boasts an exceptionally low reverse leakage current of just 5μA, much lower than similar products. This significantly reduces static power consumption in circuits and extends the lifespan of devices. When faced with transient overvoltage, the SMBJ36A responds quickly, clamping the voltage to a maximum clamping voltage of 58.7V, effectively preventing damage to the circuit and ensuring stable operation of electronic devices.

Parameters of Slkor Transient Protection Diode SMBJ36A

The outstanding performance of the SMBJ36A is attributed to its advanced manufacturing process and precise material selection. As electronic devices become increasingly complex and diverse, the demand for high-performance circuit protection components has grown. The launch of the SMBJ36A not only meets the market’s need for superior transient suppression diodes but also provides strong protection for the safe operation of electronic devices.

Meanwhile, in the field of chip manufacturing, a technological revolution is quietly taking place. Intel has announced that ASML's advanced lithography machines have been successfully deployed in its factory, delivering exciting news for the chip manufacturing industry. ASML, as a leader in the field of lithography machines, is introducing its high numerical aperture (NA) lithography machines, marking a significant breakthrough in Intel’s chip manufacturing process.

According to Steve Carson, Intel’s senior chief engineer, Intel has successfully produced 30,000 wafers within a single quarter using ASML's high-NA lithography machines. These large silicon wafers are the essential materials for manufacturing semiconductor chips, with each wafer yielding thousands of chips. Preliminary data shows that the reliability of these new machines is superior to that of previous models, indicating significant improvements in both chip manufacturing efficiency and product quality.

Lithography machines are one of the core devices in chip manufacturing, and their performance directly impacts the precision and efficiency of chip production. The successful introduction of ASML's advanced lithography machines will not only enhance Intel’s chip manufacturing capabilities but also drive technological advancements across the entire semiconductor manufacturing industry. As demand for chips continues to grow and technology continues to evolve, Intel’s collaboration with ASML will undoubtedly inject new vitality into the field of chip manufacturing.

In conclusion, both the introduction of the SMBJ36A Transient Voltage Suppression Diode and the deepening collaboration between Intel and ASML in chip manufacturing highlight the vital role that technological innovation plays in advancing the electronics industry. With its excellent performance, the SMBJ36A offers new solutions for circuit protection, while the collaboration between Intel and ASML opens up new development opportunities for the chip manufacturing sector. Looking ahead, with the continuous emergence and application of innovative technologies, the electronics industry is set to embrace even broader development prospects.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd