Service hotline

+86 0755-83044319

release time:2023-09-11Author source:SlkorBrowse:16316

Power semiconductor devices play a significant role in modern power control and drive systems. IGBT modules and IPM modules are two of the most common types of devices used in these systems. They can be utilized for controlling high-power loads and driving motors, among other applications. However, they have different internal structures and functionalities. So, what exactly do IPM and IGBT modules refer to? Let's delve into their differences in detail.

What is IPM module?

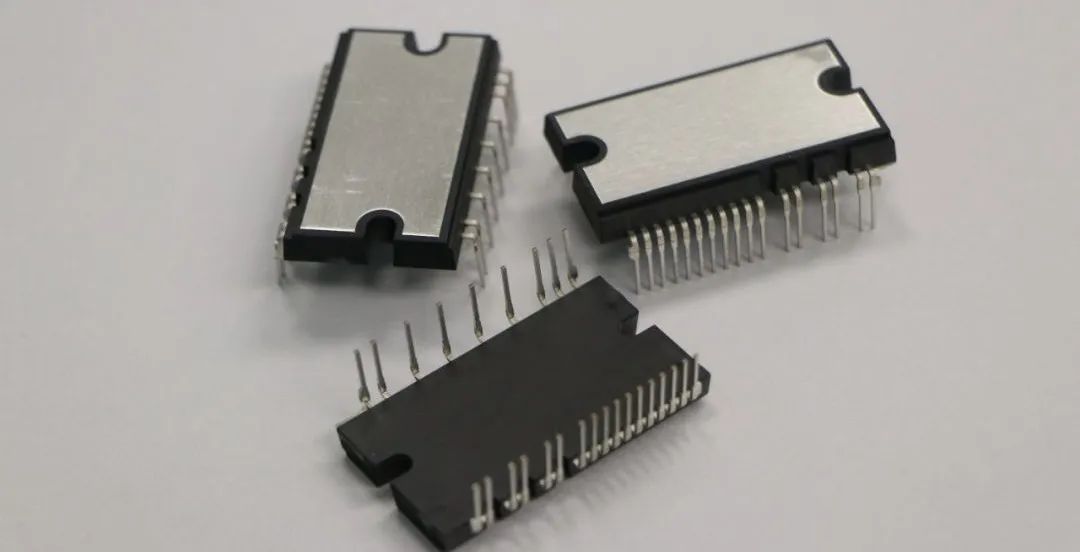

IPM (Intelligent Power Module) is a powerful integrated circuit module used for controlling and driving high-power electronic devices such as AC motor drives, inverters, and frequency converters. It is a highly integrated semiconductor device that typically includes multiple functional modules such as power switches, drive circuits, protection circuits, and control circuits.

IPM typically includes a power MOSFET, IGBT (Insulated Gate Bipolar Transistor), or SiC (Silicon Carbide) switch device, as well as a drive circuit for controlling the conduction and cutoff of these switch devices. In addition, IPM modules often integrate features such as power supply circuits, current and voltage sensors, over-temperature protection, and short-circuit protection. These functions provide comprehensive protection measures to ensure the safety and reliability of high-power electronic devices.

What is the IGBT module?

The IGBT module (Insulated Gate Bipolar Transistor Module) is a modular electronic component that integrates multiple IGBT chips, drive circuits, protection circuits, and other functions. It is a type of semiconductor device used in high-power electric power electronic equipment and is commonly employed in high-voltage, high-current AC/DC converters, inverters, and DC/DC converters.

IGBT is a semiconductor device that combines the characteristics of MOSFET and BJT. It possesses the advantages of low on-state resistance and high switching speed, as well as the high voltage tolerance and strong current-carrying capacity of BJT devices. Therefore, IGBT devices are widely used in high-power and high-frequency power electronic equipment. An IGBT module typically consists of multiple IGBT chips, drive circuits, protection circuits, heat sinks, connectors, and other components. Through the internal insulation isolation structure, the IGBT chips are isolated from the external environment to prevent external interference and electromagnetic interference. Meanwhile, the internal drive and protection circuits of the module can effectively control and protect the IGBT chips, enhancing the reliability and safety of the equipment.

What is the difference between IGBT module and IPM module?

IGBT modules and IPM modules are both power electronic devices, but they have several differences:

1. Different integration levels: An IGBT module contains only one IGBT transistor and one drive circuit, while an IPM module integrates multiple devices and circuit modules, resulting in a higher integration level.

2. Different functionalities: An IGBT module can only achieve a single power switching function, while an IPM module integrates multiple functional modules such as power supply circuits, current and voltage sensors, over-temperature protection, and short-circuit protection, providing comprehensive protection and control functions.

3. Different application scopes: IGBT modules are typically used in applications that require single power switch control, such as AC motor drives, inverters, and frequency converters. IPM modules are usually used in applications that require multi-channel power switch control, such as motor drives, UPS systems, and power converters.

4. Different reliability: IPM modules have higher reliability because they integrate multiple protection and control modules, effectively safeguarding the system against abnormal conditions such as high voltage, excessive current, and over-temperature.

5. Different costs: Due to higher integration level and more comprehensive functionalities, IPM modules are relatively more expensive, while IGBT modules are relatively simpler and more cost-effective.

In summary, IPM modules are more advanced power electronic devices with higher integration level, more functionalities, and higher reliability. They are suitable for complex and advanced power control systems. On the other hand, IGBT modules are simpler and more economical, suitable for applications that require single power switch control.

To be continued...

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd