Service hotline

+86 0755-83044319

en

en release time:2023-09-06Author source:SlkorBrowse:7853

The development background of SiC power devices

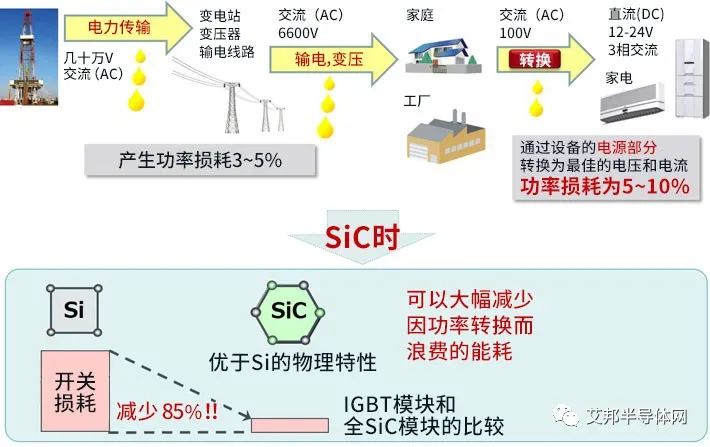

We know that by applying SiC to power devices, low-loss power conversion can be achieved, which was not possible with traditional Si power devices. It is not difficult to see that this is a major reason for using SiC in power devices. The background of this development is to promote the resolution of global energy-saving issues.

Taking low-power DC/DC converters as an example, achieving over 90% conversion efficiency is normal with the advancement of mobile technology. However, there is still room for improvement in the efficiency of high-voltage, high-current AC/DC converters. It is well known that energy-saving directives, primarily in the EU, strongly demand that electrical/electronic devices achieve energy-saving goals, including reducing standby power consumption.

In this context, reducing the energy consumption during power conversion becomes a top priority. Needless to say, materials that exceed the limits of Si must be applied to power devices.

For example, using SiC power devices can reduce switching losses by 85% compared to IGBTs. As demonstrated in this example, there is no doubt that SiC power devices will become a significant solution to energy-related problems.

The advantages of SiC MOSFET power devices

As mentioned earlier, using SiC can significantly reduce energy losses. Of course, this is a major advantage of SiC. Next, let's explore the advantages brought by the characteristics of low resistance, high-speed operation, and high-temperature operation.

We can compare them with Si. "Low resistance" can be simply explained as reducing losses, but if the resistance is the same, it allows for the reduction in size of the device (chip). When dealing with high power, power modules that integrate multiple transistors and diodes are sometimes used. For example, the size of SiC power modules can be only about 1/10th of Si modules.

Regarding "high-speed operation," by increasing the switching frequency, the volume of peripheral components such as transformers, coils, and capacitors can be reduced. In practice, there are examples where the volume is reduced to about 1/10th of the original.

"High-temperature operation" refers to the ability to operate at higher temperatures, which simplifies cooling mechanisms such as heat sinks.

As mentioned above, SiC can be used to improve efficiency or handle higher power. Considering the current power situation, significant miniaturization can be achieved by using SiC, which is another major advantage. Not only does it directly save energy, but miniaturization also contributes indirectly to energy conservation related to placement, transportation, and other factors.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd