Service hotline

+86 0755-83044319

release time:2025-04-01Author source:SlkorBrowse:2601

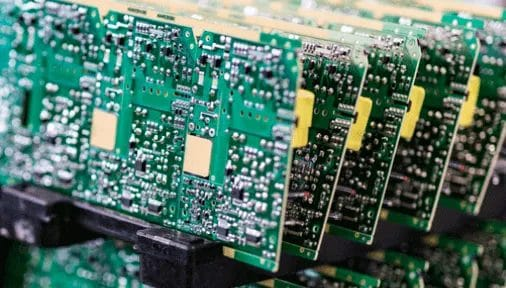

Printed Circuit Board Assembly (PCBA) is the process of mounting electronic components onto a printed circuit board (PCB) to create functional electronic devices. This critical stage bridges design and production, transforming bare boards into systems powering modern consumer electronics. For procurement and engineering teams, understanding PCBA ensures cost-effective sourcing and reliable product performance. The process involves soldering components like resistors, capacitors, and ICs onto PCBs using techniques such as surface-mount technology (SMT) or through-hole assembly.

The evolution of PCBA began in the mid-20th century with manual component placement and basic soldering. By the 1980s, automated SMT revolutionized the industry, enabling smaller, faster, and more complex assemblies. Today, advancements like high-density interconnects (HDI) and 3D printing push boundaries further. Milestones include:

Modern PCBA relies on innovations like robotic pick-and-place machines and reflow ovens. These technologies reduce human error while improving speed and precision. For example, IPC standards ensure consistency across global manufacturers.

PCBA distinguishes itself through precision, scalability, and adaptability. Key traits include:

Evaluating PCBA requires analyzing technical specifications such as:

For instance, a 12-layer PCB with 0201-sized components may be ideal for 5G routers, whereas a 4-layer design suffices for basic IoT sensors.

As the backbone of electronic devices, PCBA ensures functionality, performance, and durability. It enables:

From smart home gadgets to automotive systems, PCBA is ubiquitous. Notable uses include:

Selecting a PCBA manufacturer demands scrutiny of capabilities like:

Top-tier firms like Jabil, Flex Ltd, and Sanmina specialize in high-mix, low-volume (HMLV) production for niche markets.

Conduct on-site audits to verify quality controls, such as AOI systems and failure analysis protocols. Partnering with PCBA manufacturers that offer design-for-manufacturability (DFM) feedback reduces redesign costs.

Procurement teams must balance cost, quality, and risk. Tactics include dual sourcing for critical components and negotiating long-term agreements (LTAs) with trusted PCBA suppliers. Real-time component tracking via ERP systems mitigates supply chain disruptions.

Emerging trends like additive manufacturing and AI-driven quality control will reshape PCBA. For example, 3D-printed circuits enable rapid prototyping, while machine learning algorithms predict solder joint defects with 99% accuracy.

Mastering PCBA fundamentals empowers procurement and engineering teams to make informed decisions. By understanding its history, parameters, and applications, organizations can optimize supply chains and innovate faster in the competitive consumer electronics landscape.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd