Service hotline

+86 0755-83044319

release time:2025-03-25Author source:SlkorBrowse:1103

In high-voltage applications such as industrial automation, automotive electronics, and communication power supplies, transient voltage events pose significant threats to circuit reliability. The SLPESD24VS1U, a high-voltage transient voltage suppression (TVS) diode designed specifically for 24V systems, offers precise protection against surge pulses, electrostatic discharge (ESD), and inductive load switching. With its optimized parameters, including a 24V reverse working voltage, 50pF junction capacitance, and SOD-523 package, it is an ideal protection component for high-voltage, compact electronic devices.

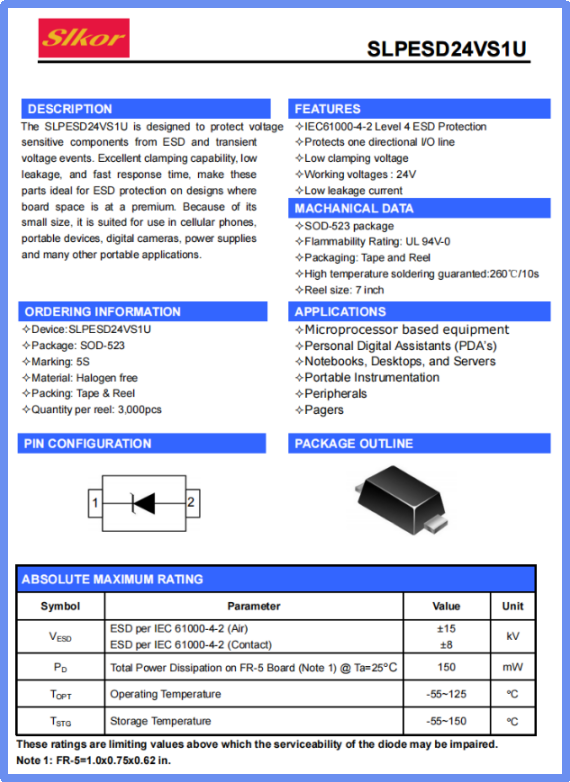

- Reverse Working Voltage (VRWM = 24V)

This parameter defines the maximum reverse voltage tolerance of the diode under normal operating conditions, making it suitable for 24V industrial power supplies, in-vehicle entertainment systems, and communication devices. Its design margin (recommended VRWM ≥ 1.1× operating voltage) ensures that the diode remains in a high-resistance state even during voltage fluctuations, preventing false triggering.

Slkor Transient Protection Diode SLPESD24VS1U product photo

- Breakdown Voltage (VBR min = 26V)

When transient voltage exceeds 26V, the diode enters avalanche breakdown mode, forming a low-resistance path to dissipate energy. The 2V safety window (26V - 24V) ensures sensitive components are protected from surges, while also avoiding malfunction due to power noise or ripple.

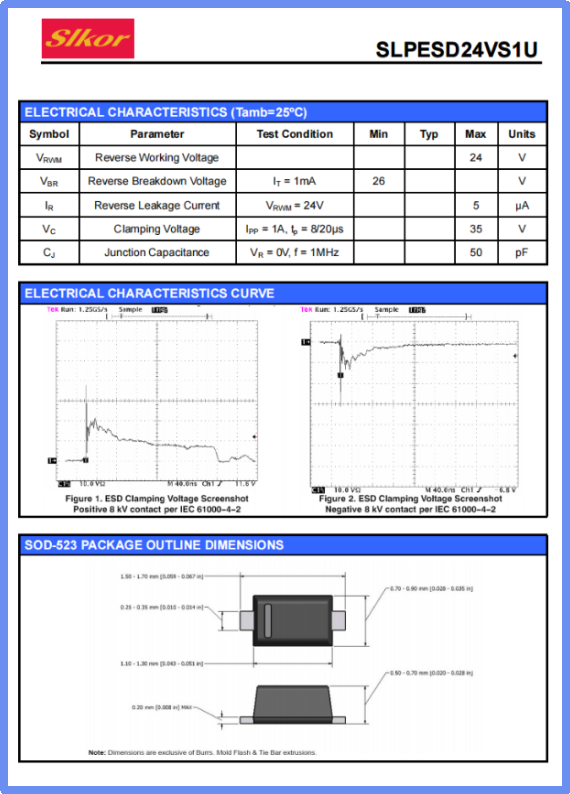

Slkor Transient Protection Diode SLPESD24VS1U specification

- Reverse Leakage Current (IR = 5μA)

Under VRWM conditions, the reverse leakage current is only 5μA, corresponding to a standby power consumption of 125μW (calculated at 24V). This feature is particularly important in battery-backed industrial sensors or automotive devices, extending the operational lifetime of the equipment.

Parameters of Slkor Transient Protection Diode SLPESD24VS1U

- Clamping Voltage (VC = 35V)

Under standard test pulses (8/20μs, 5kA), the clamping voltage is 35V. This value is below the gate breakdown threshold of most high-voltage MOSFETs (typically >40V), ensuring the downstream power devices remain safe during lightning surge or load switching events.

- Junction Capacitance (CJ = 50pF)

The junction capacitance is 50pF, and at a 1MHz signal frequency, the capacitive reactance is 3.2kΩ. This has negligible impact on low-frequency switching signals (such as relay driving and motor control). However, in high-frequency applications (like MHz-level communication), signal integrity impacts should be evaluated.

- SOD-523 Package

The diode is housed in a compact 1.0mm × 0.6mm SOD-523 package, which is 50% smaller than the SOT-23 package, with a 0.5mm pin pitch, supporting high-density PCB layouts. Its thermal resistance (θJA) is 350°C/W, and heat dissipation design should be optimized through the PCB copper layer.

1. High-Voltage Application Compatibility

The 24V/26V threshold design is optimized for industrial 24V power systems, simplifying circuit design compared to traditional multi-stage 12V/24V TVS diodes. In tests, under a 30V transient pulse, the clamping response time is <1ns, with a peak power absorption capability of 200W (10/1000μs waveform).

2. Energy Efficiency Design

The doping process of the chip is optimized to create a sharp I-V curve between VBR and VC. When transient voltage reaches 26V, the dynamic resistance is only 0.5Ω, effectively limiting the overvoltage energy.

3. Environmental Adaptability

The temperature coefficient of VRWM is -3mV/°C, with a VRWM drift of no more than 7% over the range of -40°C to +150°C. Combined with a moisture sensitivity level (MSL) of 1, the component is suitable for high-temperature and high-humidity industrial environments.

1. Industrial Automation

- PLC Output Modules: Protect 24V digital output ports from transient impacts caused by motor start/stop switching.

- Sensor Interfaces: Cascade with gas discharge tubes (GDTs) in 4-20mA analog signal chains to form a multi-stage surge protection network.

2. Automotive Electronics

- On-Board Chargers (OBC): Protect power MOSFETs in DC/DC converters and absorb CAN bus ESD events.

- LED Automotive Lighting Drivers: Work in tandem with Zener diodes to suppress negative load transients.

3. Power Supplies

- AC/DC Adapters: Protect optocouplers and primary-side control ICs after rectification.

- Solar Inverters: Absorb voltage spikes during photovoltaic panel switching.

4. Design Optimization Strategies

- Layout and Routing: It is recommended to place the TVS diode within 5mm of connector/IC pins, with trace widths ≥0.5mm to minimize parasitic inductance.

- Collaborative Protection: In high-frequency switch-mode power supplies, ceramic capacitors (such as 100nF X7R) can be used in parallel to enhance low-frequency filtering.

The SLPESD24VS1U, with its precisely tuned parameters, demonstrates significant advantages in 24V industrial and automotive electronic systems. Its 50pF junction capacitance and 24V/26V voltage threshold design strike a balance between high-voltage protection and signal integrity. With the advancement of Industry 4.0 and electric vehicle technologies, this component will play a key role in applications such as motor drives, power management, and in-vehicle communication, offering circuit protection solutions that combine performance with reliability.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd