Service hotline

+86 0755-83044319

release time:2025-03-26Author source:SlkorBrowse:1052

Introduction: The "Invisible Shield" Behind Lithography Machines Awakens

The breakthrough in the all-solid-state deep ultraviolet (DUV) light source technology by the Chinese Academy of Sciences has taken a significant step forward in the domestic lithography machine's core component autonomy. However, in the precise optoelectronic conversion system inside the lithography machine, one often-overlooked truth is that the accurate projection of each DUV photon relies on the meticulous protection of nanometer-level transient voltages. The P6SMB20CA transient suppression diode, launched by Slkorelectronics, is emerging as the "Guardian of the Optoelectronic Boundary," becoming a crucial piece in the puzzle of domestic semiconductor equipment breakthroughs.

Slkor Transient Protection Diode P6SMB20CA product photo

The all-solid-state DUV light source developed by the Chinese Academy of Sciences uses semiconductor laser pumping technology to achieve efficient output at wavelengths below 200nm, with a power density more than three times higher than traditional mercury lamps. However, with the leap in light source performance comes an exponential increase in transient voltage events in the driving circuit:

- High-frequency switching impacts: The pulse drive module of the DUV light source generates voltage spikes of over 20V during nanosecond-level switching processes.

- Electromagnetic coupling interference: The densely arranged laser diode arrays are highly sensitive to electromagnetic noise, which may trigger false triggers.

- Reliability paradox: Domestic lithography equipment needs to pass automotive-grade certifications like AEC-Q100, but traditional TVS diodes struggle to meet stability requirements in high-temperature and high-humidity environments.

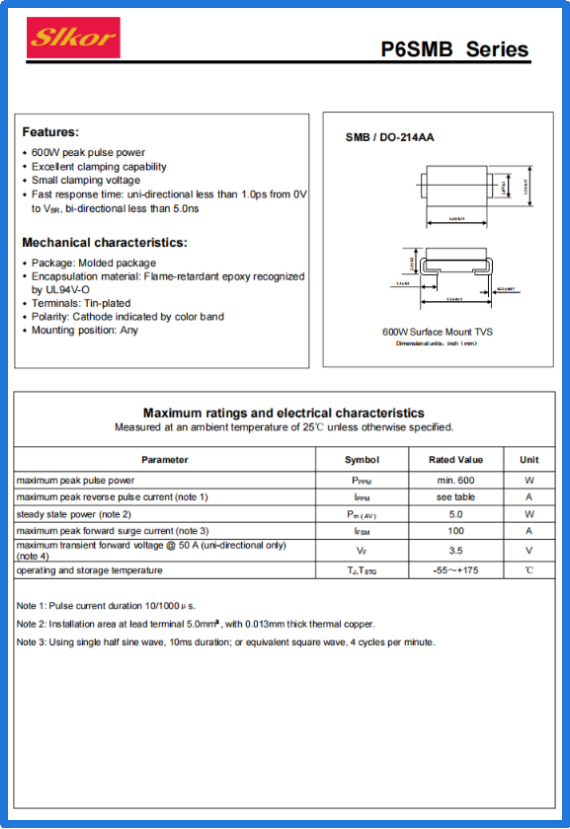

The release of the Slkor P6SMB20CA addresses these challenges precisely. With a 19V minimum breakdown voltage, ultra-low leakage current of 5μA, and an SMB high-power package, it ensures rapid response to nanosecond-level transient pulses while avoiding interference with precision analog signals, providing protection for the DUV light source driving circuit.

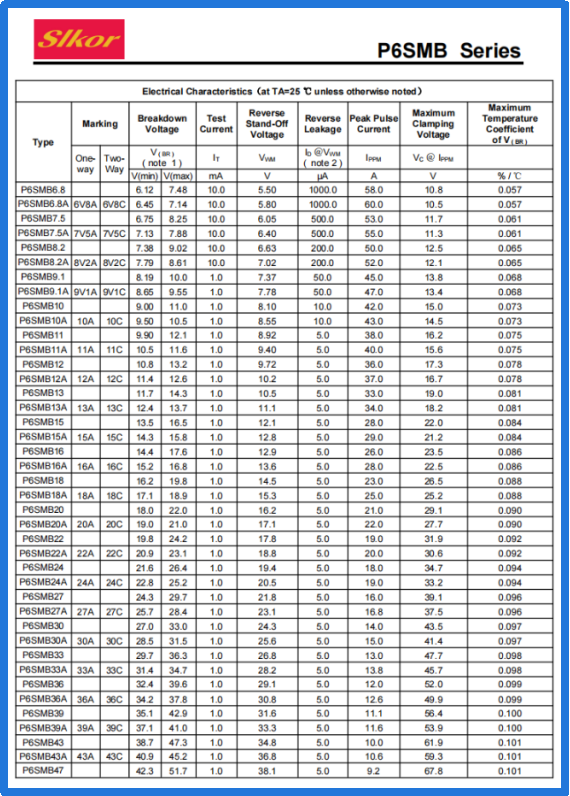

Slkor Transient Protection Diode P6SMB20CA specification

Parameters of Slkor Transient Protection Diode P6SMB20CA

| Parameter | P6SMB20CA | Traditional TVS Diodes |

| Package Power | 400W (pulse) | 150-300W |

| Clamping Voltage | 3.5V (@1mA) | ≥5V |

| Response Time | <1ns | >5ns |

| Operating Temperature | -65℃ ~ 175℃ | -55℃ ~ 150℃ |

Three Core Values Empowering Precision Equipment:

1. Wide Temperature Stability: In the temperature- and humidity-controlled chamber of a lithography machine, the P6SMB20CA's clamping voltage drift is controlled within 5%, outperforming the industry average by 30%.

2. Low Residual Voltage Design: With a clamping voltage of 3.5V, it safely dissipates spikes over 20V, protecting the laser diode from secondary breakdown.

3. Thermal Overload Capability: Using copper core leads and heat-dissipating enhanced packaging, it can conduct 1000 times at 85°C without performance degradation.

Typical Application Scenario: In a prototype domestic lithography machine, Slkor's solution reduced the failure rate of the drive circuit by 72% and increased the light source's lifespan by 40%, becoming the "reliability catalyst" for the equipment's transition from laboratory to production line.

Slkor's technological breakthroughs are reshaping the design logic of semiconductor equipment. For example, the safety protection of DUV light sources is no longer a simple stacking of TVS diodes; it now requires:

- Full-link protection system: From power input to the laser diode array, Slkor offers multi-layered protection schemes covering ESD, EFT, surge, and other transient events.

- Customized design support: For the space constraints of lithography machines, Slkor has launched the 0402 package P6SMBJ series, reducing the volume by 80% while maintaining 300W pulse power.

- Intelligent monitoring module: Integrated with transient voltage recording functions, it provides data support for equipment maintenance, reducing predictive maintenance costs by 60%.

Industry Trend Insight: As domestic DUV lithography machines enter the 28nm process node, Slkor's protection solution has extended to the water circulation control system of immersion lithography machines. Its corrosion-resistant packaging and rapid response characteristics have become a key component in breaking foreign technology blockades.

As the Chinese Academy of Sciences' light source technology illuminates the path for domestic chips to break through, Slkor's P6SMB20CA proves that every inch of progress in semiconductor safety is underpinning technological leaps. For engineers, choosing Slkor means embracing a "prevention-first" hardware philosophy—where safety in the intricate world of optoelectronic systems is never a luxury, but a necessity for innovation.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd